SAP PP Tutorial for Beginners

Let’s learn about SAP PP in detail.

SAP PP Definition or SAP PP Meaning

SAP Production Planning enables producers to design ideal production plans that strike an appropriate balance among cost, quality and delivery performance by taking inputs from materials planning, demand forecasting, sales forecasting and operations planning into account.

Furthermore, users are able to monitor manufacturing plans on an ongoing basis in real time as production plans change statuses over time.

SAP Production Planning (PP) software gives businesses the power to schedule output, plan capacity and estimate demand in manufacturing processes.

SAP PP means utilization of resources efficiently ensures production plans are optimized, customer deadlines met and customer needs fulfilled.

SAP PP Tutorial

This SAP PP module tutorial covers planning, scheduling, production costing and cost accounting as well as demand forecasting.

SAP PP tutorials also shows you how to utilize its master data sets, system setup procedures and procedures effectively.

PP Module in SAP

PP SAPModule facilitates managing master production schedule, purchase orders, detailed scheduling and capacity planning in real-time for manufacturers to plan, track and meet material and capacity needs efficiently while optimizing resource allocation in line with production planning schedules and demands – guaranteeing on-time deliveries at lower prices with shorter lead times than ever.

SAP Module PPsimplifies demand forecasting, material requirements planning and inventory management by helping organizations decide what products need to be produced at what quantities based on forecasted demands and supply requirements.

SAP PP Full form

In full form SAPPP stands for SAP Production Planning

SAP Production Planning (SAP PP) facilitates efficient planning, operational control, resource allocation and production processes.

SAP PP overview OR SAP PP Module Overview

This SAP module makes creating, updating and scheduling production tasks much simpler as well as offering Manufacturing Resource Planning (MRP) features including accurate planning of material needs as well as automation/integration solutions across systems/departments/operational plants.

Companies utilize SAP Production Planning (PP) to design production systems that reliably produce goods of the right kind, quantity and price. The module allows businesses to specify stock levels while also providing data regarding inventory availability, scheduling needs and resource needs in one convenient display.

Alongside these functions, the module also offers capacity planning, process planning, quality management and order observation to guarantee effective manufacturing using various analytical tools; users of such technologies may use predictive demand analysis or evaluate execution strategies and devise more suitable execution plans to ensure effective manufacturing.

SAP PP Course or SAP PP Module Course

It aids production planning, supply chain collaboration and departmental and external data integration. The SAP PP courses/training covers Production Orders, Material Requirement Planning (MRP), Product Costing as well as training on efficient production management using various tools and approaches –SAP PP full course teaches how to organize and manage production efficiently using tools/ approaches such as master data configuration/ management; production process design or execution strategy as well as production operations strategy as part of production operation strategy training which makes SAP production planning optimized/ improved over its counterpart.

The SAP PP module PDF provides access to the complete user handbook for the SAP pp module. In this PP Module in SAP PDF user manual, SAP PP’s primary features, operations, and capabilities are described. Setup, configuration, and implementation recommendations, as well as troubleshooting guidance, are all included.

Batch Management in SAP PP

SAP PP batch management aims to control product production and quality by creating and tracking batches throughout their supply chains, linking them with maintenance orders to help track them efficiently – this allows inventory systems to track each batch individually.

Batch management issues encompass batch size, capacity restrictions, serial numbers tracking within the system as well as batch quality concerns.

SAP PP parameters should be optimized to enable optimal batch management, including setting batch types, categories, sizes and shelf-life controls and quality checks.

A batch search feature may help quickly locate batches. It helps streamline manufacturing operations while decreasing waste. It streamlines operations while streamlining waste reduction practices.

SAP PP Training

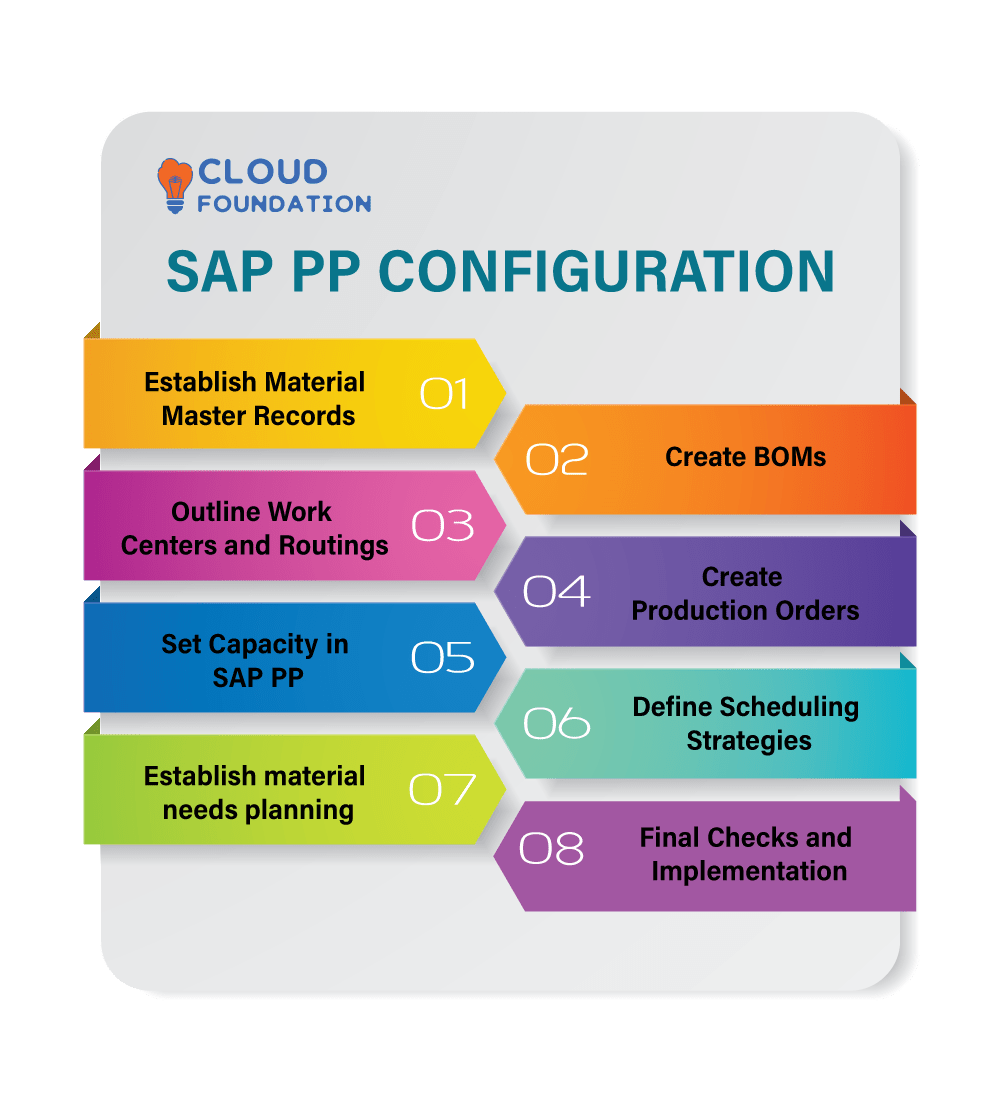

SAP PP Configuration

PP configuration in SAP helps manufacturers plan, study and execute production processes using materials and components.

Below are steps you must complete in order to activate SAP PP Process:

Establish Material Master Records: These will contain details regarding material codes, descriptions and product group classifications.

Create BOMs (Bill of Materials): SAP PP facilitates this by meeting the material master requirements, while simultaneously acting as an inventory control mechanism and aiding production planning. A BOM plays an integral part of manufacturing as it assists production planning while controlling inventories.

Outline Work Centers and Routings: In SAP PP, work centers refer to areas or places in which materials, semi-finished goods or services are produced; routing refers to processes which transform raw materials into finished items. It is imperative that both are designed and configured accordingly for efficient operations.

Create Production Orders: When scheduling the production of items, production orders are essential in coordinating activities efficiently and planning effectively. Material master records may help create these orders efficiently.

Set Capacity in SAP PP: Capacity planning in SAP PP involves determining both time and resource capacities within production processes, such as by listing various manufacturing orders as well as production cycle time estimates.

Define Scheduling Strategies: For improved production planning, SAP PP should be used to formulate and execute a scheduling strategy. One or more of its techniques like forward scheduling or backward scheduling could be utilized here to do just this.

Establish material needs planning: Material requirements planning encompasses creating guidelines for manufacturing processes as part of its goal, which the SAP PP material needs planning capability can assist with.

Final Checks and Implementation: Prior to initiating and installing SAP PP systems, one final inspection should take place to make certain all necessary configurations and settings have been carried out appropriately. When this has been accomplished, system installation and use may commence immediately.

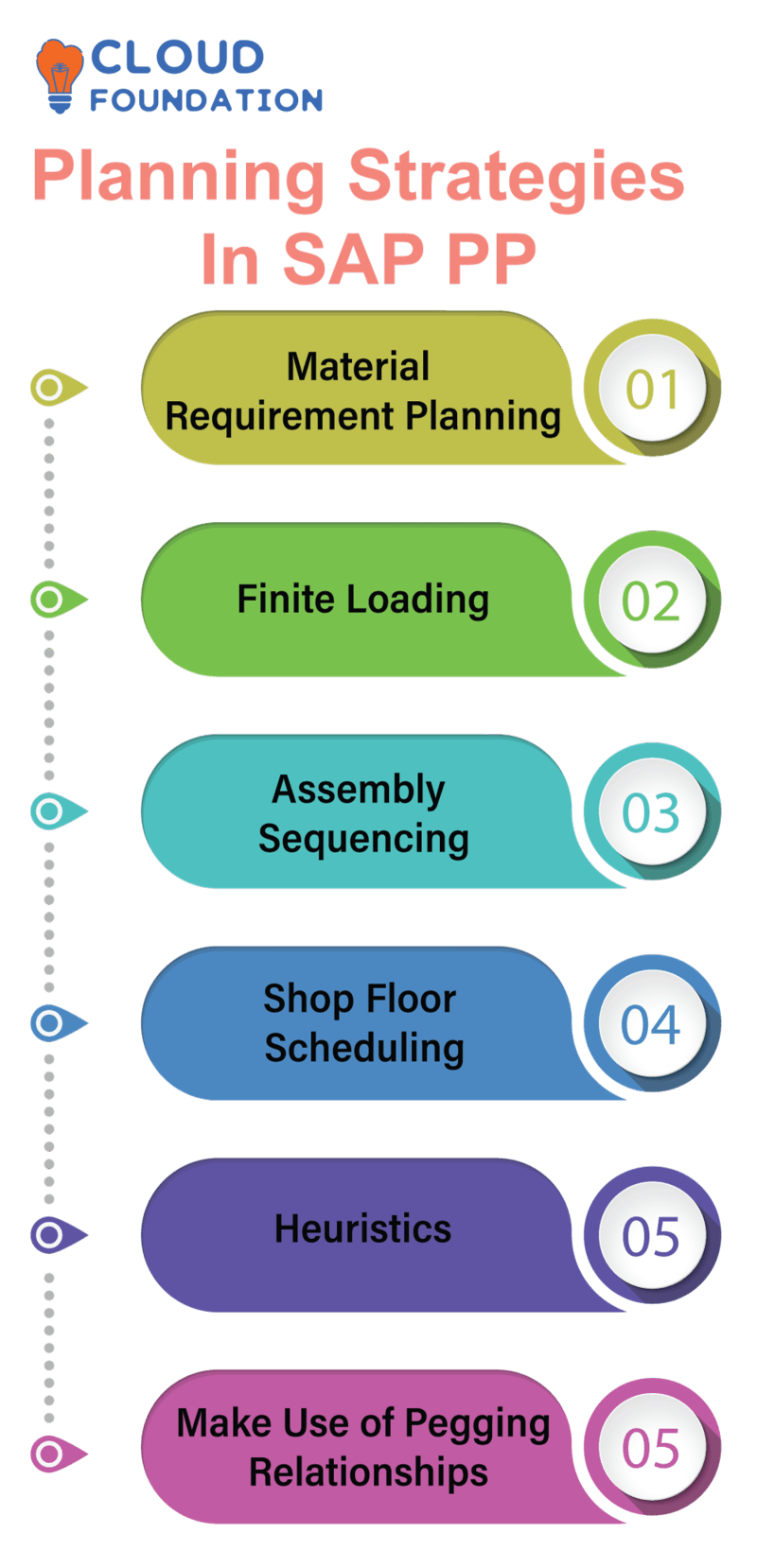

Planning Strategy in SAP PP

Following are some of the Planning Strategies in SAP PP:

Material Requirement Planning in SAP PP:Material requirement planning assists production planners by helping identify materials and parts needed to produce certain products, and by helping ensure supplies arrive on time to satisfy manufacturing demands.

Finite Loading: Finite Loading makes production scheduling possible by capitalizing on existing capacities across resources.

Assembly Sequencing: Through assembly sequencing, production planners may identify all necessary steps involved with producing an item and identify which components must be added first to create it.

Shop Floor Scheduling: Scheduling the shop floor ensures all essential tools and supplies are available when production activities need to be completed.

Heuristics: Heuristics are optimization methods or techniques designed to anticipate production needs and identify optimal scheduling solutions.

Make Use of Pegging Relationships: Pegging relationships help keep track of production plan’s master and dependent requirements while SAP PP flow process makes this easier than ever.

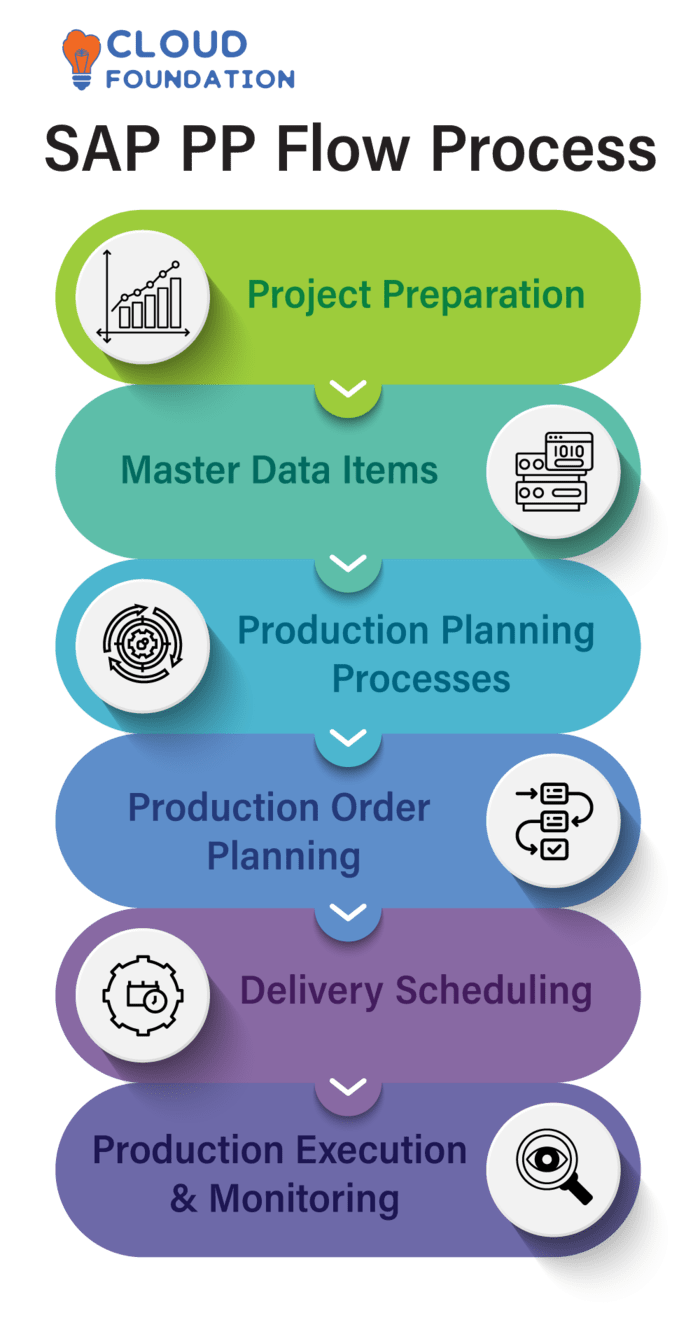

SAP PP Flow Process:

The PP Process Flow in SAP is a structured method that helps businesses manage and carry out their complicated operations more successfully.

The set of procedures used when the SAP Production Planning module is used to produce, manage, and schedule products and services is known as the SAP PP Process Flow.

A graphical design canvas is another feature of SAP’s Process Flow that aids in visualizing processes and makes it easier to spot problems. This makes it possible for businesses to quickly detect and resolve issues.

Additionally, PP Flow in SAPsubstantially minimizes the need for human labor and boosts overall productivity.

Project Prep: As with any process flow in SAP, project preparation in the PP process begins by setting up the organizational structure to enable accurate tracking of data; this includes business codes, plants, storage sites and costing components.

Master Data Items: After undertaking project planning, all required master data items should be created – this may involve developing materials, Bill of Materials (BOMs), alternate routings, work centers or cost profiles as necessary.

Production Planning Processes: Following the configuration and activation of master data components, all required production planning processes should be configured and activated.

Production Order Planning: Next, it is crucial to set up and activate production order planning procedures, with regards to cycle times, order types and statuses as well as capacity needs of individual worksites all being established in this way.

Delivery Scheduling: Delivery Scheduling is an integral step in SAP PP as it ensures on-time deliveries to clients.

This involves setting shipping tolerances, delivery schedules and shipment orders to guarantee timely deliveries of products to them.

Production Execution and Monitoring: As part of SAP PP process’s sixth and final step, Production Execution and Monitoring requires tracking production execution using various measurement methods such as time studies.

To guarantee on-time production for materials and products produced using this approach.

Production Version in SAP PP

A production version in SAP PP connects the production process, including its details such as number of work centers, routing, activities, cost centers and labor types to it.

Furthermore, configuration data helps speed up manufacturing by expediting this step; furthermore, enabling businesses that produce multiple items to easily utilize multiple versions for creating items with similar setups but minor variations such as material used, color choice or options settings; an invaluable asset when manufacturing large numbers of different items at once.

SAP PP Online Training

Subcontracting Process in SAP PP

SAP Production Planning’s Subcontracting process refers to the practice of procuring components produced, semi-finished or completed outside a company and then integrating them into production flow.

An organization may use subcontracting orders within SAP PP so components purchased from suppliers, processed before being assembled as per client specifications.

SAP PP subcontracting process entails following stages.

Submit a purchase request to subcontractors.

Work with vendors to develop subcontracting purchase orders for subcontracted supplies.

Prepare goods receipt for items subcontracted out before creating production order(s).

Establish production orders specific to subcontracted productions orders

Create a goods receipt from the vendor for any components subcontracted out.

Issue completed items as goods issue for shipping out.

Add products problem for subcontractor manufacturing order to manufacturing order for subcontractor.

Process the vendor invoice.

MPS in SAP PP

SAP Production Planning’s MPS tool for sales and operations planning allows users to forecast production demand and capacity requirements over an upcoming period.

Utilizing its long-term perspective, materials can be planned long in advance using this resource; to guarantee company has enough resources available to them and meet demand; its optimized scheduling can take into account short- and long-term production goals as well as monitor actual progress made toward them.

SAP PP Integration with other Modules

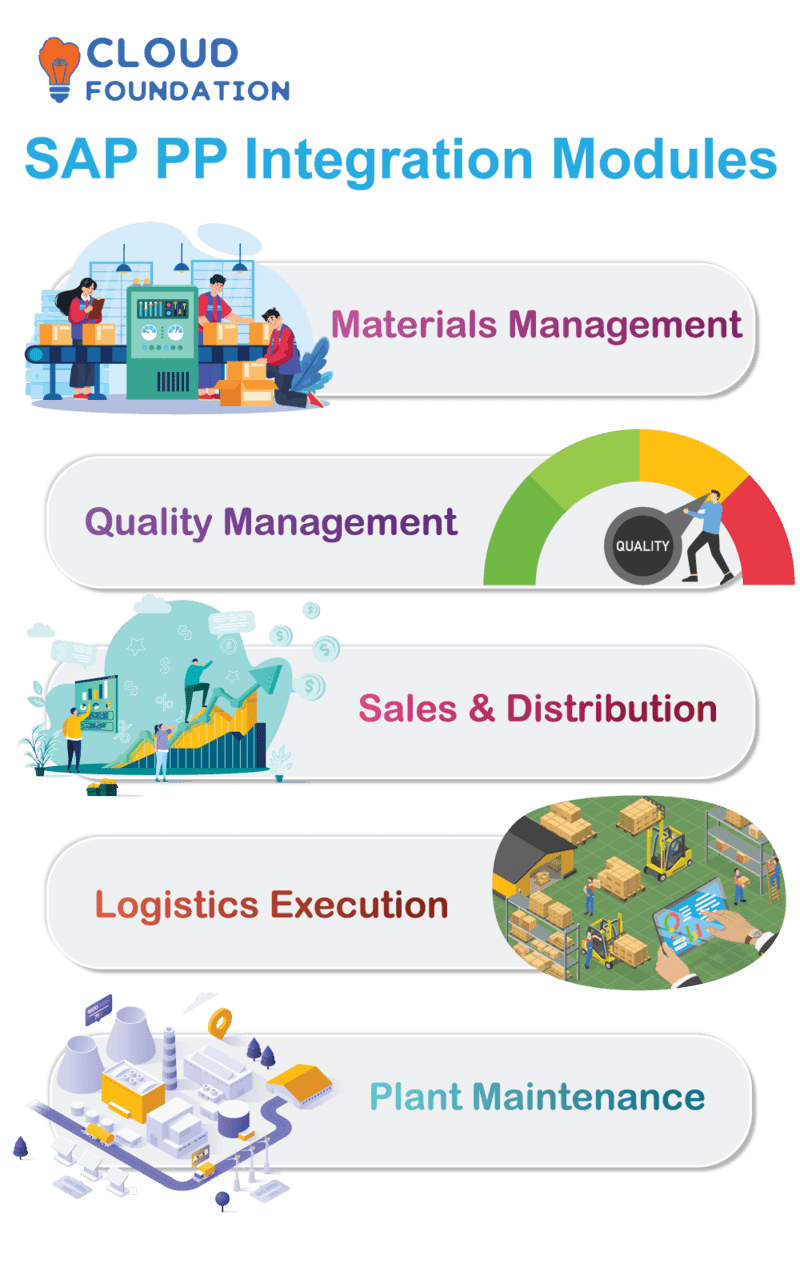

SAP Production Planning (PP) typically integrates several modules:

Materials Management (MM): This module assists production schedulers by providing key material item details regarding availability and quantity to PP modules for scheduling production activities and producing finished goods of appropriate quality.

Quality Management (QM): This module assists PP in material quality inspection and allows us to keep a record of production-related quality tests.

Sales and Distribution (SD): SD allows PP to streamline order planning and delivery while rapidly adapting to changes in market demand.

Logistics Execution (LE): This module assists PP in tracking deliveries and shipments while offering insight into items in route – helping schedule delivery windows more accurately and manage delivery schedules accordingly.

Plant Maintenance (PM): This module assists with managing machine and vendor maintenance needs as well as preventative maintenance needs, to help maintain an uninterrupted output stream.

SAP PP Module TCodes

- CO01 – Create Production Order

- C22 – Goods Movement

- CO03 – Display Production Order

- CO04 – Change Production Order

- CO11N – Release Production Order

- CS03 – Display BOM

- CO70 Production Planning Table

- CO01N – Create Work Order

- CO02 Change Work Order

- CO09 Confirm Production Order

Production Scheduling Profile in SAP PP

Any material or product in a system may have its scheduling characteristics managed using SAP PP’s production scheduling profile, which allows for precise definition of scheduling processes and methodologies related to operation sequences such as lead times calculations, batch and sequence splitting management and processes oversight, development/adjustment process flows as well as production procedures scheduling; finally, this method determinesexact policies and procedures specific for every manufacturing order.

Production Scheduling Profile parameters are utilized when scheduling products or materials into the system, including batch splitting parameters and sequencing production orders.

When scheduling product or material orders in production system environments, various parameters in production scheduling profile should be defined using it.

Assignment of specific scheduling rules to production orders; Utilization of resources in production. Controlling interdependencies among operations.

MRP Group in SAP PP

SAP Production Planning’s Material Resource Planning Group or MRP group serves to organize materials or processes which have similar scheduling. As part of material master record data, MRP Group allows planners to manage how production planning materials are planned for and scheduled during production planning.

SAP PP Career Growth

Given SAP PP is used by various organizations, those specializing in SAP PP have much room for career advancement. Businesses seeking to establish or enhance existing SAP PP processes require professionals with these abilities.

SAP PP experts may advance their careers by becoming senior consultants or business analysts, with specialties including systems integration, supply chain management, data analysis and production planning and scheduling among others.

Once experienced enough they may even advance to leadership positions such as program manager, product manager and architect.

As demand for knowledgeable experts within this sector increases rapidly in the near future, employees of this function stand a good chance at taking advantage of newly available career options in this sector.

SAP PP Course Price

Kiranmai

Author

“Bringing you the latest in tech news and insights to ignite your creativity & spark positive change – Welcome to my world of words”