What is SAP PP and What is routing in SAP PP?

SAP PP Tutorial: Overview, Introduction to SAP PP

SAP Production Planning automates and integrates production. SAP PP helps manufacturers manage materials from design through delivery; supporting shopfloor, MES and discrete manufacturing operations with its software solution.

Production engineering software performs tasks related to scheduling, material requirements planning, source & capacity planning, master data management and master data governance – thereby streamlining production planning and execution and improving manufacturing resource utilisation.

What is SAP PP or What is PP in SAP?

With SAP Production Planning, more accurate blueprints can be generated while manual planning becomes less necessary, which increases profitability while simultaneously decreasing resource waste.

Increase material availability and decrease stock-out issues while creating space in the supply chain for additional products.

SAP PP Definition or Define SAP PP

SAP Production Planning is composed of MRP and PS, each component performing its own unique function to help organisations plan production more effectively while eliminating overstocking and shortfall losses, revolutionising manufacturing operations and aiding entrepreneurs make sound business decisions.

What does SAP PP do and what is SAP PP used for?

Production Planning (SAP PP) can benefit both small and large production planning and material management firms alike, since its functionality impacts ERP and manufacturing operations.

Rapid growth in SAP PP usage has caused its module to be adopted widely by firms like Ford and General Motors among many others.

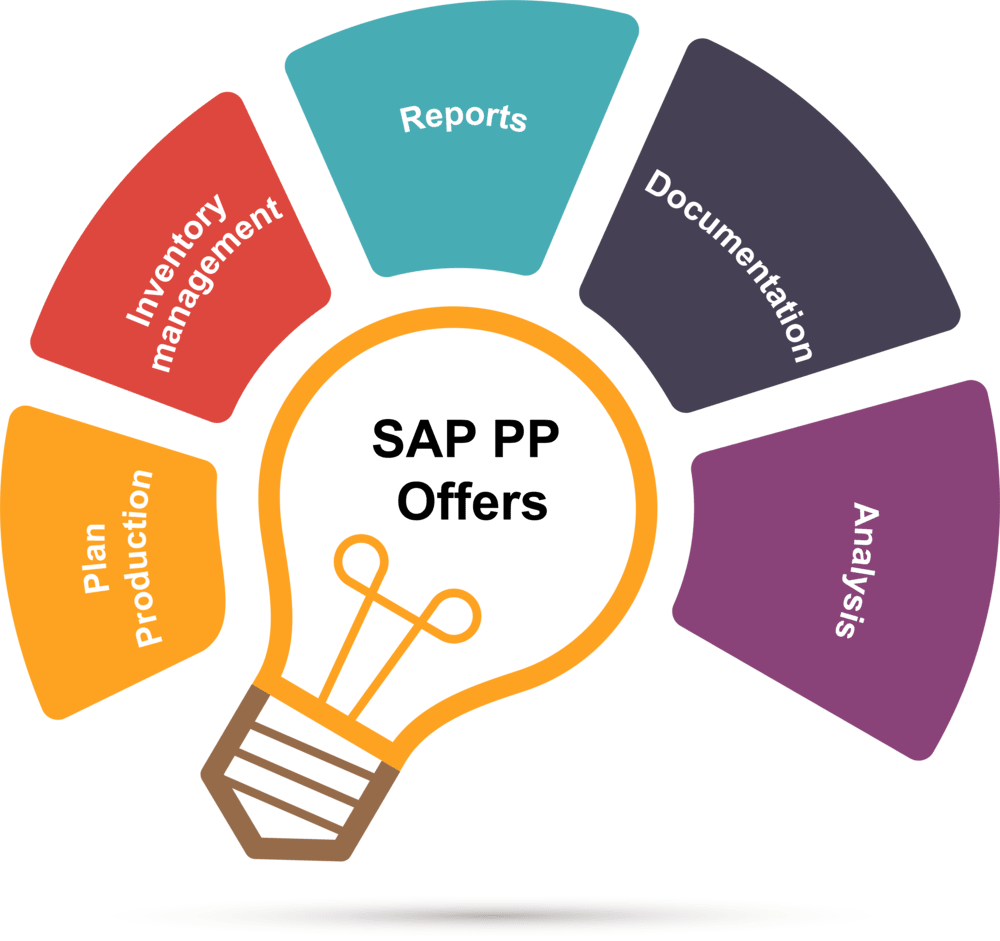

“SAP PP” offers tools and methods for production and dispatch planning. In particular, this module serves to:

Plan Production

Inventory management

Reports

Documentation

Analysis-It streamlines and enhances manufacturing

What is SAP PP used for?

One component of SAP Production Planning known as SAP PP serves to manage procurement planning.

Also referred to as Purchase Module or simply Goods Planning in SAP terms, planning materials such as raw, semi-finished and final goods is covered – these data movements are all recorded via SAP ERP as the component makes its rounds through production planning processes.

SAP PP employs a document-oriented procurement process in order to document, maintain and make available all purchasing-related information. It offers resources for maintaining and managing procurement data as products have a life cycle.

This step depends heavily on business flows, which encapsulate an organization’s need for real-time information. Sales forecast is at the core of these operations as it determines production order placement, delivery date calculations, manufacturing plan outlines and more.

How does SAP PP work?

SAP Production Planning software works seamlessly both within cloud-based Production Planning systems as well as physical Production Planning systems.

Demand Management helps identify which products require batches by tracking sales of each individual item sold through Demand Analysis.

SAP PP Production Planning allows enterprises to meet consumer demands more easily while aiding operation planning efforts. It includes master production scheduling, material requirement planning and execution planning modules.

Financial Data Management also encompasses Financial Master Data, Material Master Data, Shop Floor Data (including Production/Warehouse management system and shop floor recording for approval), Master Material/PP PP Involved Parties master data as well as Logistics/ Supply Chain management with tools used for inventory/goods receipt and shipping arrangements at plants as well as tools designed to deliver production orders or sales orders.

SAP Production Planning utilizes manual and automated resources and use case scenarios to optimize product manufacturing, with infinite storage expansion capability for optimal production control. Furthermore, this module supports international ERP solutions.

SAP Production Planning integrates national standards using various standards and technologies, as well as on-demand IT paradigms versus on-site models when implemented on the cloud.

Both cloud approaches offer Infrastructure as a Service so switching between on-site and on-demand models is free of cost.

SAP PP Training

Why SAP PP and What are the Benefits of SAP PP?

SAP PP provides users with tools to plan final goods; assemblies and materials (BOMs) used in manufacturing work centres as well as production orders describing these plans in more depth.

Production orders define base time and units while when an order executes successfully the plant module issues a shop order in response.

Manufacturing companies use SAP PP to effectively and efficiently manage material and information flow, helping them plan, control, monitor supply chain activities more closely while decreasing inefficiencies and increasing performance – thus improving transparency, quality, and regulatory needs.

SAP PP improves supply chain performance by optimising capacity use and order fulfilment, streamlining supply chain management and increasing profitability.

Successful deployment requires subject matter expertise as well as business process knowledge for success – these criteria include analysing ERP usage and recording business processes as well as understanding topics covered during formal SAP PP training courses and certification processes.

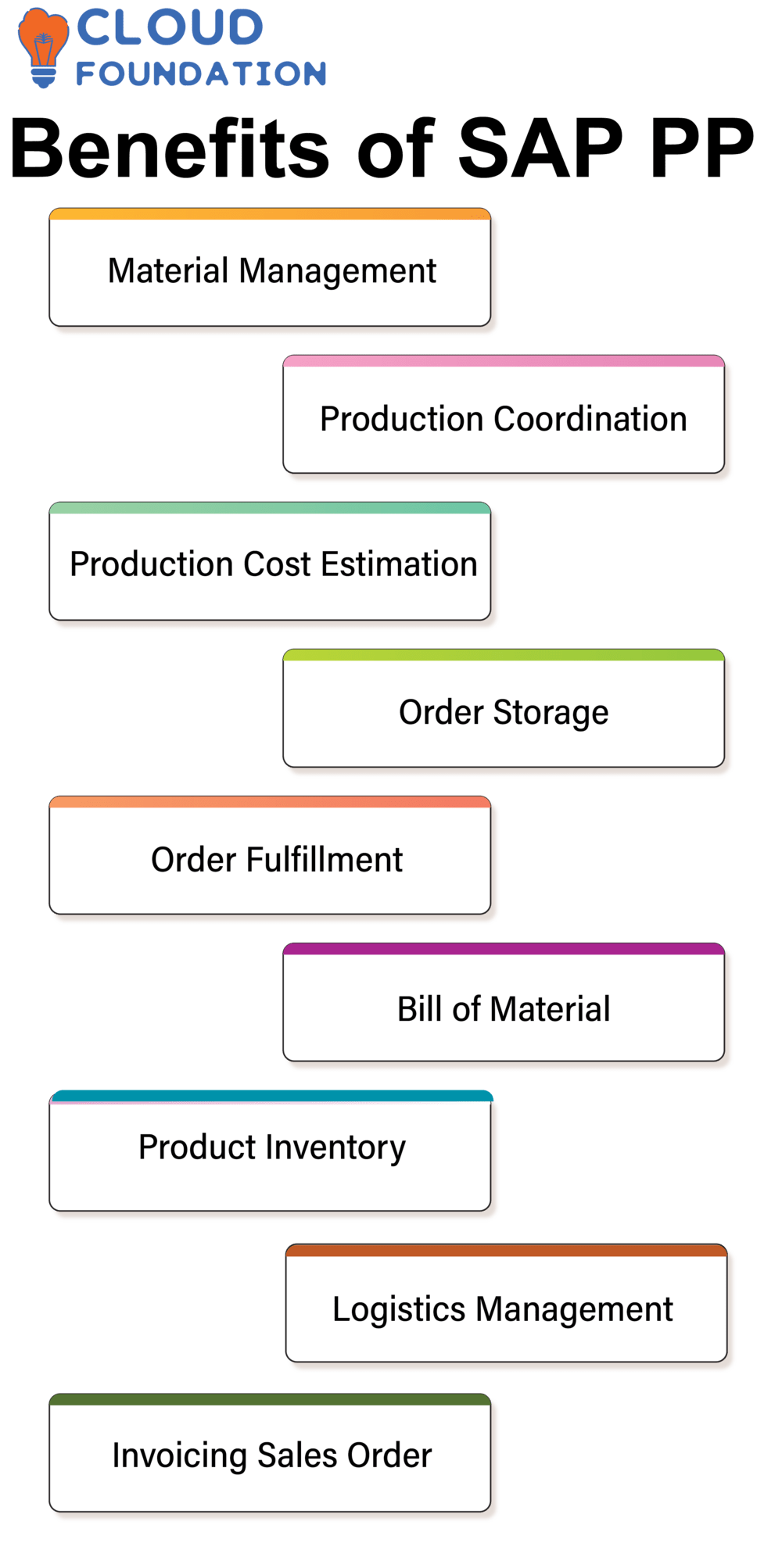

What are the Benefits of SAP PP?

SAP Production Planning is essential, with this tutorial explaining its many advantages:

Monitoring Material Availability for Production Schedules

Coordinating Discrete Production

Production Planning Cost Estimation

Order Storage,

Order Fulfilment

Bill of Material (BOM).

Inventorying Completed Products

Logistics Management

Sales Order for Invoicing.

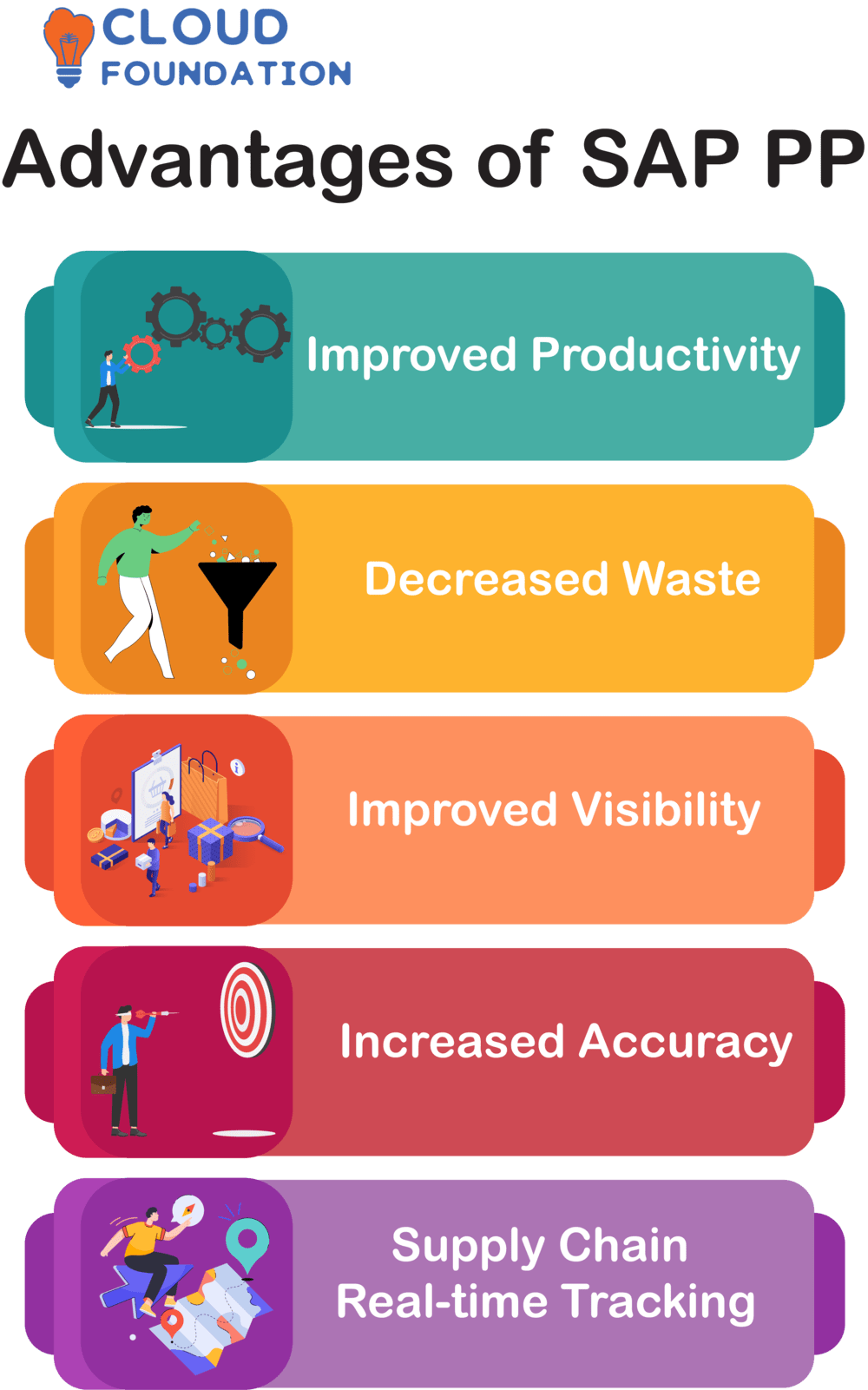

Advantages of SAP PP

Improved Productivity: It streamlines data entry processes to reduce unnecessary manual steps, cutting labour costs while simultaneously increasing productivity.

Decreased Waste:SAP Planning and Scheduling capabilities optimize inventory levels while minimising stocktaking fees, thus eliminating production bottlenecks.

Improved Visibility: It provides consumers with a complete picture of their production environment by consolidating all key information into one application, so professionals can more quickly locate and resolve concerns.

Increased Accuracy: SAP PP helps companies calculate more precisely to ensure they have all of the ingredients for production.

Supply chain real-time tracking: This offers real-time production monitoring to allow companies to better predict product availability and inventory needs for on-time deliveries within acceptable lead times.

What is SAP PP software and How to use SAP PP?

SAP PP software assists manufacturing planning, coordination and control activities.

Planning, scheduling and controlling submodules such as requirement planning, material requirement planning, production planning and capacity requirement planning as well as sales & operations planning and dispatch/material control/shop floor management can all be found within its features.

Production Planning uses SAP tables for planning, product, cost data as well as material capacity planning and production forecasting. ERP’s SAP PP module assists companies in planning and monitoring manufacturing activities.

SAP PP is designed for manufacturing, construction and chemical companies to manage plant development projects such as plant development, remodelling and production machine/tool renovation projects.

It helps organizations manage production run data, including manufacturing costs. By keeping all this data under one roof and processing it regularly, companies can assess their production processes and adjust accordingly.

SAP Production Planning allows companies to maintain detailed manufacturing data records. Businesses can conduct post-action reviews to evaluate what went well or did not go as planned and make necessary improvements for future manufacturing operations.

These reviews help manufacturers improve future production efforts.

SAP PP Online Training

How to use SAP PP?

Establish Basic Data: Establish master data for materials, bills of material, work centres and routing. This foundational information serves to support production.

Plan Production: Once basic data are entered into SAP PP, use it to develop production orders or plans based on customer orders or forecasts. APP handles materials management along with labour allocation for more efficient resource utilization.

Execute Productions: Master data can be utilized to schedule production immediately following an order being placed, with SAP PP tracking its progress and making necessary adjustments based on usage patterns.

Track Production: Leverage the capacity management and material requirements planning features within SAP PP to monitor production throughput and manage its efficiency.

Evaluate Production: With SAP PP’s reporting features, production managers can evaluate production efficiency and workplace effectiveness – using data for improvement purposes. Assess results to enhance workplace effectiveness.

Cost Monitor: SAP PP’s monitoring capabilities assist manufacturers with calculating manufacturing costs and efficiency, making comparisons of performance easier, as well as adjustments.

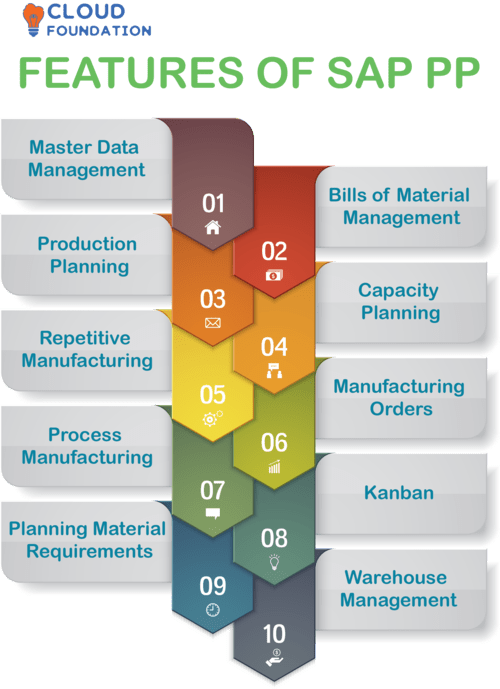

SAP PP Features

Master Data Management: Effectively administer and preserve fundamental resource and material characteristics in one central place.

Bills of Material Management: Develop and preserve Bills of Materials as well as their relationships between each other.

Production Planning: Arrange and coordinate production as well as material needs management of goods produced.

Capacity Planning: Assess capacity bottlenecks and evaluate material and capacity requirements by product.

Repetitive Manufacturing: Direct the creation and improvement of goods that contain repeating features.

Manufacturing Orders: Produce and manage manufacturing orders efficiently for discrete parts and batch processes.

Process Manufacturing: Optimize production of finished and semi-finished goods through efficient control over process manufacturing operations.

Kanban: Ordering and production replenishment can be conducted using signals sent from a pull system.

Planning Material Requirements: Determine optimal material requirements when planning manufacturing orders.

Warehouse Management: Optimize warehouse operations such as picking, placing away and storing.

What is Routing in SAP PP?

SAP PP routing describes a product’s production steps in detail. It shows how it will be produced including setup, run time costs and quantities resulting in cost-efficient production strategies that maximize profits while being cost-cutting as a whole.

What is SAP PP module or What is PP module in SAP?

The SAP Production Planning (PP) Module covers every facet of production planning from orders development, capacity planning and material requirement planning right through to material requirement optimisation in production process optimisation which reduces costs while improving efficiencies of operation.

What is Production Planning in SAP?

Sales and production planning enable companies to plan product production according to existing and anticipated future demand, in line with materials management (MM). Production Planning acts as part of materials management (MM), planning product production through

What is MRP group in SAP PP?

Material Requirement Planning, an integral element of SAP Production Planning, allows organizations to optimize their supply chains by quickly spotting inventory shortages and alerting purchasing departments accordingly.

MRP-SA manages master data independently from SAP Production Planning using Intra Company Structure (ICS). MRP can also be performed from sales and distribution, materials management, plant maintenance management or master planning tools.

Understanding MRP capabilities and benefits are integral to SAP ERP’s functionality and company management.

What is Production Version in SAP?

SAP not only generates data, but it also collects it. The production version contains company-specific data; due to the massive volume of information, must be stored automatically by SAP within this production version.

Rather than entering all data manually, SAP’s planning module can be modified by activating production versions.

Once activated, production version data are stored permanently as opposed to master data that only activate during customization and disappear when production versions are deactivated.

No matter the production version or customisation process for SD (Sales and Distribution), always use PDATE/Master Data planning tools when developing production versions and customising projects.

Since it’s independent from production versions, maintenance of Dok (data objects) must be handled manually for planning purposes. Once in production mode, however, its attributes will adapt for demand/supply network production in accordance with network production plans.

What is Backflush in SAP PP?

Production Planning (PP) features a special function called backflush that automatically generates orders to adjust planned orders according to changes in material availability and reduce PP stock at unacceptable ratios, with backflow facilities offering reduced material requirements levels and stock numbers.

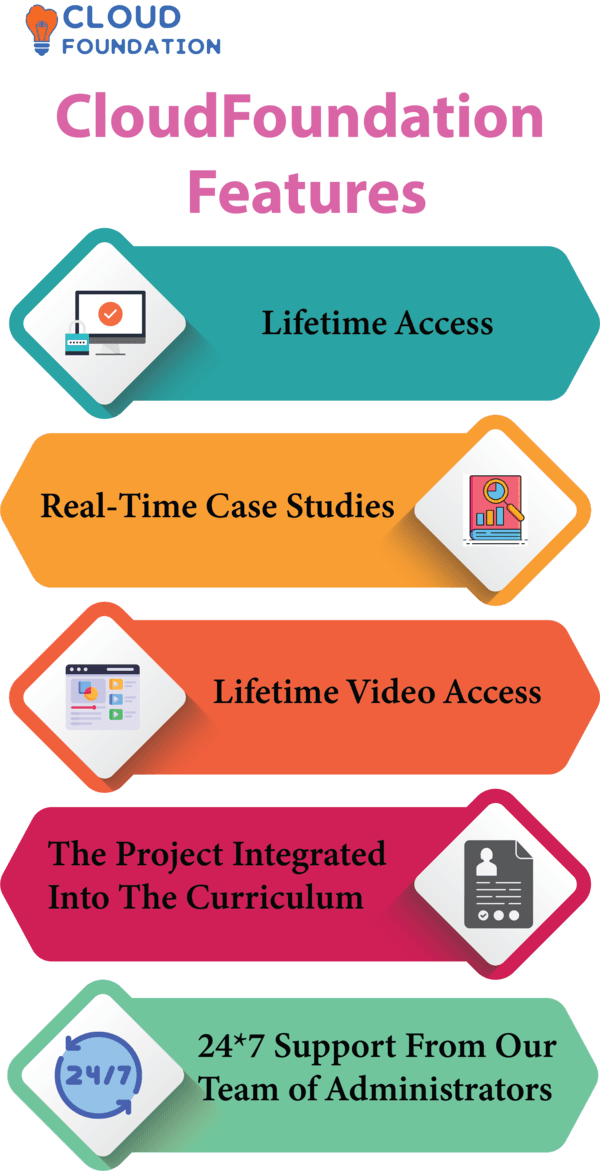

What are the Best ways to Learn SAP PP?

For best practice when learning SAP PP, SAP PP courses, SAP PP training videos, SAP PP basics and SAP PP blogs can all provide invaluable knowledge of this complex topic.

Training videos help apply principles directly into projects while reading blogs is an ideal way of keeping abreast of new techniques and ideas that arise within this realm of SAP.

By following all three approaches together you may master SAP PP quickly and be prepared for any assignment given your path ahead.

CloudFoundation features SAP Production Planning-related blogs for you to learn more about production planning and supply chain management. You may even discover new insights through reading their writing.

SAP PP Course Price

Kiranmai

Author

“Bringing you the latest in tech news and insights to ignite your creativity & spark positive change – Welcome to my world of words”