SAP MDG Training Course

Purchase Groups and Warehousing in SAP MDG

As a student of SAP MDG, I’ve always been intrigued by its core concepts, like purchase groups. These are not just fields in the system; instead, they represent who’s managing procurement activities at each plant location.

As I began exploring SAP MDG material master, it became apparent that purchase groups play a crucial role in purchasing processes, particularly when creating purchase requisitions.

Initially, I found the term to be somewhat unclear, although I understood what a purchase organisation does: act as an intermediary between a company and suppliers; however, a purchase group seemed utterly foreign to my understanding.

My inquiries surrounded SAP MDG teams. According to sources within my plant, these are comprised of individuals or specific areas with designated roles for managing procurement in SAP MDG.

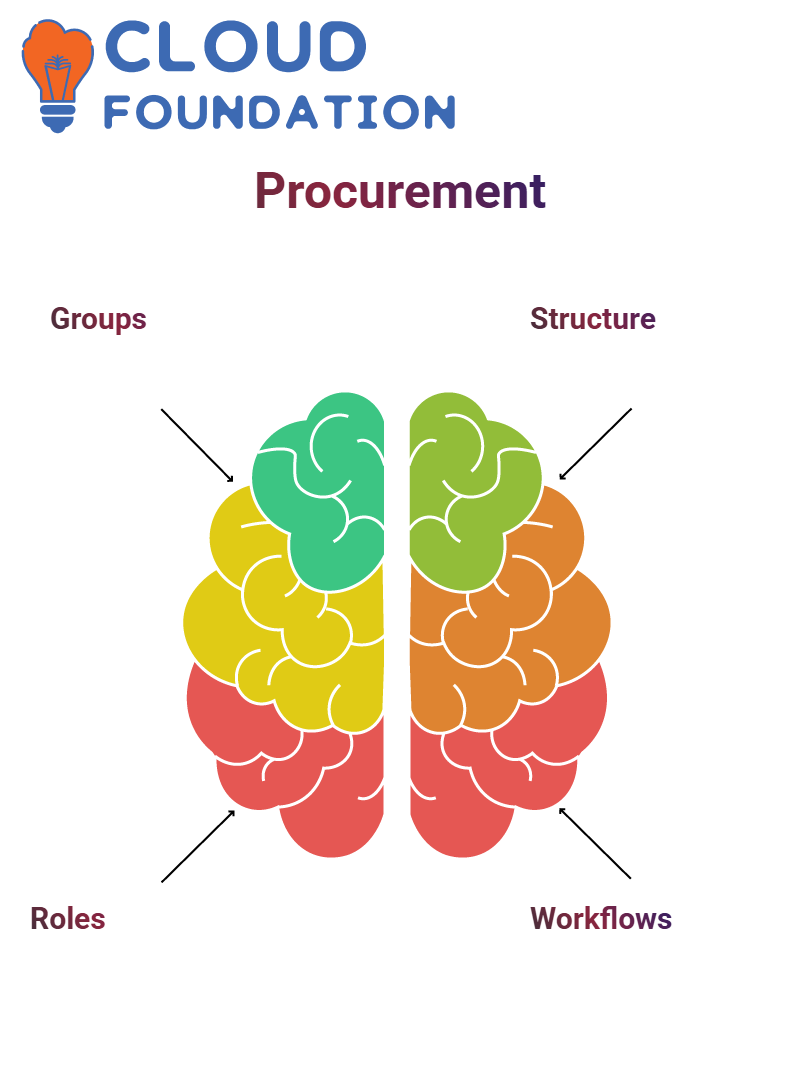

Why Purchase Groups Matter in SAP MDG?

Reiterating on purchase groups – in SAP MDG’s plant environment, there can be multiple groups; consider them mini teams or departments within an enterprise.

Each team handles specific procurement categories – for instance, office supplies, while another might take care of hardware components, providing structure and accountability in procurement activities.

SAP MDG enables us to define groups and assign clear responsibilities to them

This approach makes procurement workflows much smoother, ensuring that only authorised people make purchases and helping organisations maintain control without slowing down processes.

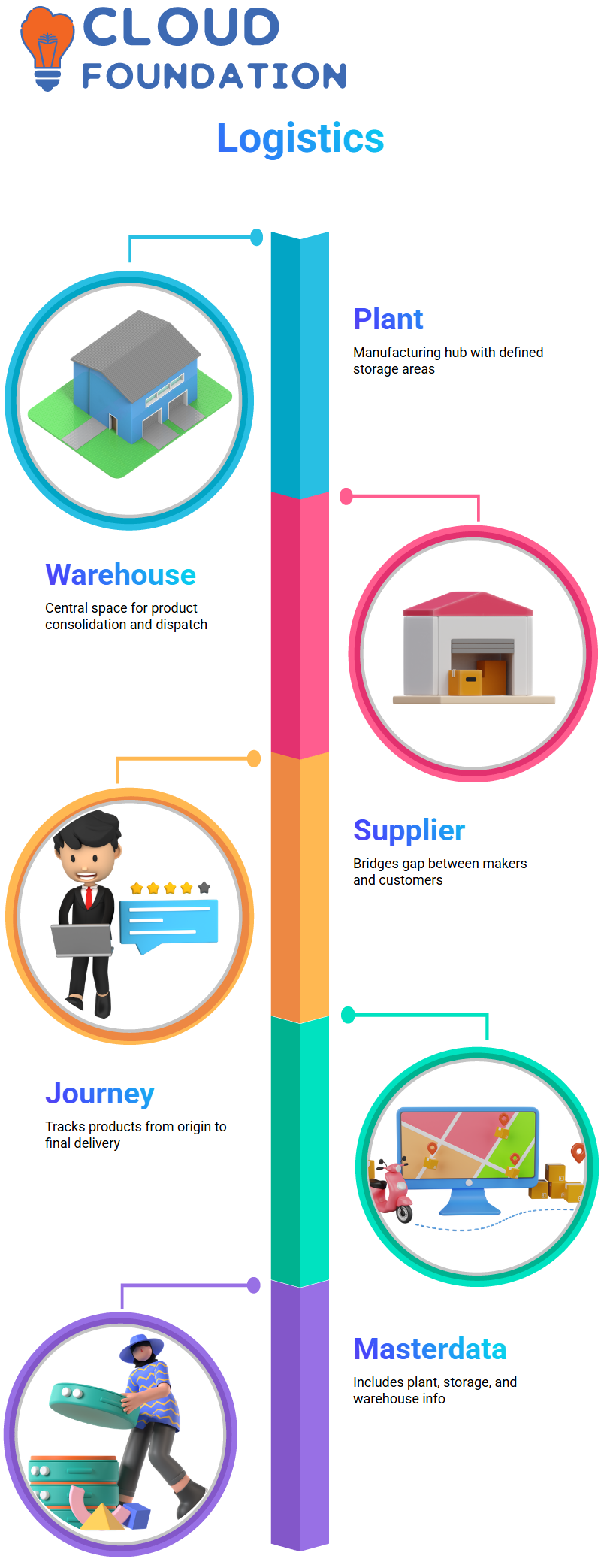

SAP MDG: Manufacturing to Warehousing

Let me provide an example that often serves as my starting point: Imagine creating a product for both local distribution (within your city and country) and global syndication.

SAP MDG enables businesses to connect their manufacturers, suppliers, and customers throughout their product’s journey, from origination to sale and beyond.

Not all items can be sold directly from the manufacturer to the customer without going through an intermediary supplier as needed. In these instances, you need someone to bridge the gap between the manufacturer and the customer, facilitating a direct sale.

When creating material master data in SAP MDG, I must specify three areas: plant, storage location, and warehouse.

A plant serves as the hub of manufacturing; think of it like a house with four rooms representing storage locations within it.

Every product or product type has its own designated space within a warehouse; on the other hand, warehouses often serve as hubs where products from various companies are consolidated before being sent directly to customers.

How Warehousing Works in SAP MDG?

Warehouses within SAP MDG do not produce products; instead, they store finished goods and occasionally components.

So, if my plant in Electronic City, Bangalore, wanted to supply products to Indiranagar or Whitefield quickly and efficiently, warehouses might be set up there to streamline distribution. SAP MDG allows us to manage logistics with precision.

These warehouses serve as a buffer and distribution centres. Here, finished products, returned items, and sometimes parts used in final assembly are stored. No R&D or production activities take place here; SAP MDG ensures that this remains separate across various organisational levels.

SAP MDG’s Material Lifecycle and Organisational Units

SAP MDG simplifies material creation and management by illustrating how various elements, such as company codes and purchasing organisations, come together to create or manage materials.

Purchase organisations engage suppliers and create purchase orders; customers engage sales organisations and generate sales orders.

SAP MDG utilises this structure to ensure that every transaction — whether a purchase or sale — follows a well-defined, traceable path.

I appreciate how these distinctions exist as they simplify business logic while offering full traceability throughout their journey.

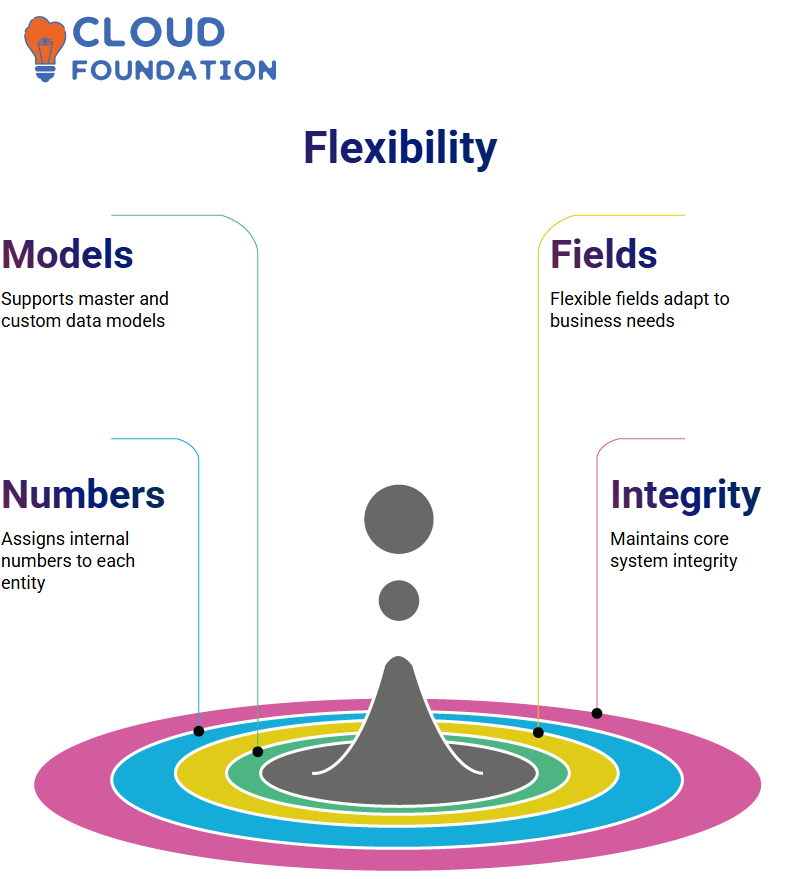

SAP MDG Flex Models and Data Fields

As part of my recent SAP MDG work experience, I recently began investi

gating its data model and flexible objects.

Exploring its various fields was truly eye-opening; its broad customisation capability has impressed me immensely.

Now, adapt it to suit the exact requirements of your organisation while maintaining its core integrity.

As I had limited time for further investigation, establishing flex fields and testing NAVBC demonstrated the power of SAP MDG.

Regardless of your approach—master data or custom models—SAP MDG provides support every step of the way.

Number Range and Entity Configuration in SAP MDG

Assigning entities to business objects in SAP MDG is a crucial initial step. Every time I create new material or establish business partnerships, the system assigns an internal number, represented by a dollar sign ($).

SAP MDG allows us to configure this behaviour, creating standardised internal numbering. If you have ever attempted to make change requests on an incorrect system, then you know how frustrating the experience can be.

One system I managed was severely corrupted — certainly not production-grade — causing havoc with SAP MDG processing.

Deleting essential records such as 194 could prove disastrous; to prevent that from happening again, I follow specific instructions when managing SAP MDG environments.

Authorisation Control in SAP MDG

SAP MDG enables administrators to control permissions by utilising authorisation groups for managing access control.

I created and linked an authorisation group with entity types in SAP MDG so it can easily validate whether users possess the proper permissions when making change requests, providing an efficient means of administering access within our system.

Edit Mapping and UI Access in SAP MDG

After expanding my data model in SAP MDG, I typically utilise the Create/Edit Mapping feature. Although ideally this should open a web-based user interface (UI), sometimes systems don’t configure this correctly, and the app won’t even launch properly.

Mapping is an integral step, as it defines how data will flow from staging areas into active ones within SAP MDG.

Staging to Active Area Mapping in SAP MDG

Once I expand an entity, such as a material (MIT), and add custom fields, I must first define its mapping between staging areas and active ones.

SAP MDG relies on this mapping to transfer data correctly after activation of a change request. If the post-processing (PP) to active mapping isn’t set correctly, data might not reach the standard tables as expected.

SAP MDG relies heavily on this configuration to ensure data moves smoothly from staging tables into active structures, with SAP MDG’s custom field values being transmitted to my backend system.

Data Accuracy Through Reverse Mapping in SAP MDG

SAP MDG requires not only one-way mapping but also two-way mapping. If I create a material with field X but later change it to field Y, reverse mapping must occur from the active area back into the staging area as part of its 2STA mapping configuration.

As part of my work with SAP MDG data models for either manufacturing material management (MMDM) or business process modelling (BPDM), I always ensure that both forward and reverse mappings are in place, so that any updates to active data are correctly recorded and stored in staging for further processing.

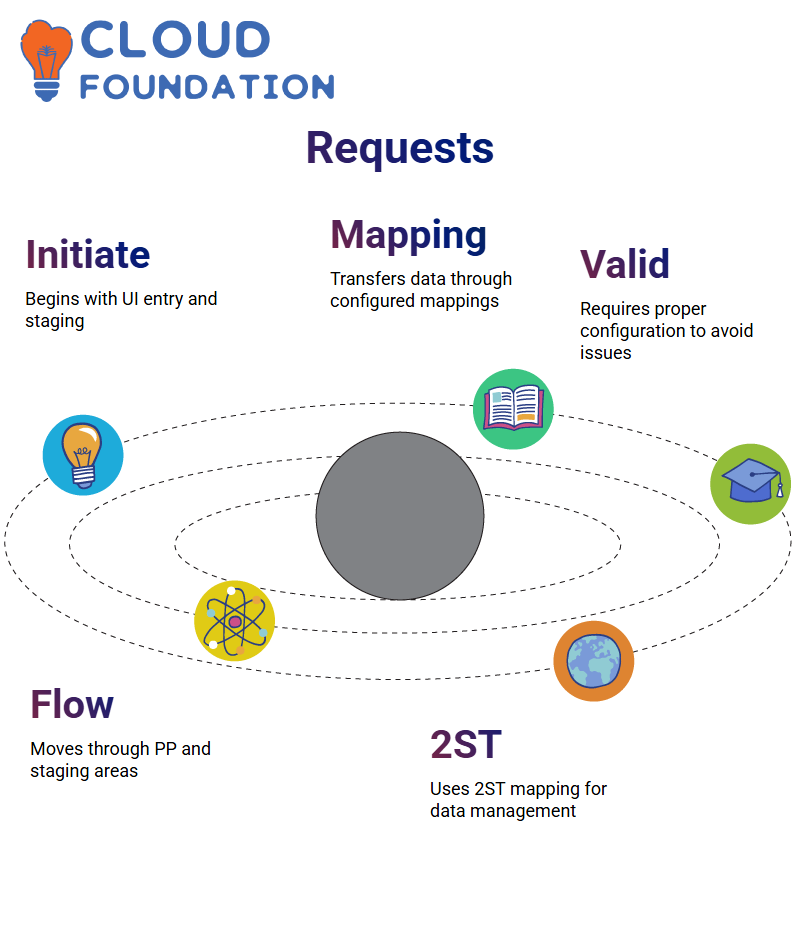

Change Request in SAP MDG

When I initiate a change request in SAP MDG, the following typically occurs: material details entered via the user interface are placed into staging tables before SAP MDG moves them into active structures for the post-processing phase.

That is why I stress the importance of maintaining proper mapping configuration in SAP MDG.

Without proper configuration in place, data may not flow correctly into its designated tables, resulting in inconsistencies and potential system issues.

SAP MDG Change Request Flow

Working on SAP MDG configurations often involves handling changes to active data. Even before I officially initiate the change request process, a small request is filed, which precedes the formal procedure.

SAP MDG proves its worth at every turn when initiating change requests in active areas; I use 2ST mapping to manage it efficiently. Data flows between the processing area (PP) and the staging area via 2ST mapping before returning to PP after it has been approved for processing.

All this happens behind the scenes without anyone even realising, yet a proper configuration of SAP MDG must exist for it to function successfully.

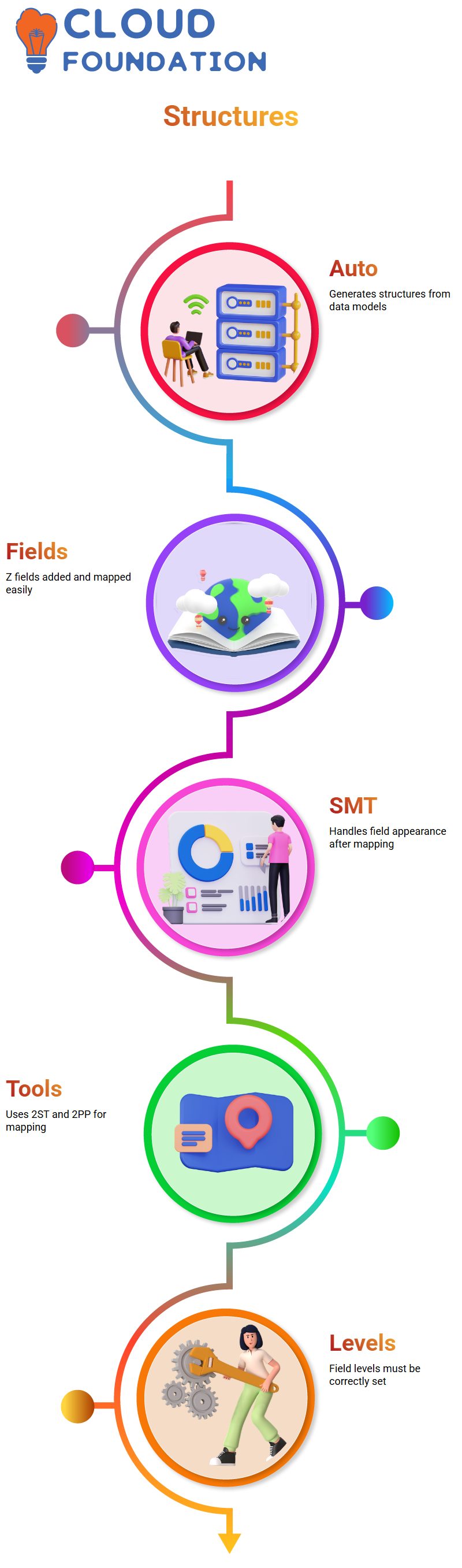

Structures in SAP MDG SMT Mapping

SAP MDG automatically generates structures when expanding a data model, making it easy and quick to add Z fields and create structures.

Once I added Z fields, structures were generated automatically by SAP MDG. SMT mapping (System Mass Transfer Mapping) came next, which is crucial in terms of how mapping affects the appearance of fields within an SAP GUI after mapping has been completed.

Source and target structures within SAP MDG appear when I use tools such as 2ST or 2PP. SAP MDG reads my data model to generate it automatically; there’s no need for me to construct it manually.

For fields to be usable within these SAP structures, their levels must be appropriately levelled within them.

Prepping SAP MDG for UI Enhancements

After completing SMT mapping in SAP MDG, my next step is always to enhance the UI to make the newly mapped Z attribute visible to users. Visibility within SAP MDG depends upon effective mapping and structure generation processes.

SAP MDG requires that field mappings align with staging and active areas; I check these mappings before beginning process modelling.

Each step in my journey – from data model expansion and structure generation to SMT mapping and finally UI enhancement in SAP MDG – takes time.

Server Integrity in SAP MDG

Working on shared SAP MDG servers can be tricky. I remind my team to avoid deleting standard objects, such as 194 under the material entity, as this can disrupt the configuration flow and potentially impact how SAP MDG manages materials.

As soon as SAP MDG configurations go missing, creating and mapping materials becomes challenging. I often collaborate with others to resolve server issues and verify the existence of alternative servers.

The success of SAP MDG depends on having stable environments with complete configuration settings.

Navya Chandrika

Author