Workday Procurement to Pay Supply Invoice Tutorial

Streamlining Supply Invoicing in Workday

Managing supplier invoices is often one of the most complex and time-consuming tasks in financial operations.

Between uploading attachments, ensuring correct control totals, applying discounts, and managing approvals, mistakes can easily slip in. That’s where Teresa Serama, a powerful invoicing management tool, comes in to simplify the process.

Copy and Modify Existing Invoices

One of the most significant advantages of Teresa Serama is the ability to copy existing invoice details. Instead of starting from scratch every time, users can duplicate an invoice and make only the necessary changes.

This saves significant time while reducing the risk of human error.

Flexible Attachment Management

Users can upload new attachments or replace existing ones with the simple “Add/Change Attachment” button. Whether it’s a contract, a purchase order, or proof of delivery, supporting documents can be updated seamlessly.

Control Total Amount Validation

Accuracy is key in invoicing. The system allows users to set a control total amount, ensuring that the invoice total always matches the supplier’s actual amount. For example:

At the header level, users can set the total to 1000.

At the line-item level, adjustments can be made (e.g., increasing to 11,000).

If totals don’t match, the invoice won’t proceed—helping companies avoid costly reconciliation issues.

Approval Workflow and Testing

Once changes are submitted, invoices go through the same review and approval process as new ones.

To ensure reliability, negative testing is encouraged—such as trying to submit an invoice with the same supply and invoice number as an existing one, which should rightfully fail.

This testing ensures that no duplicate invoices are processed and accounting entries are only created after approval.

Currency Conversion and Rate Handling

For companies working with international suppliers, Teresa Serama integrates exchange rates directly from trusted sources such as central banks or financial websites.

For example, a supplier invoice in Euros can be automatically converted to USD at the current market rate (e.g., 1 EUR = 1.875 USD).

This ensures transparency in reporting and accurate financial snapshots.

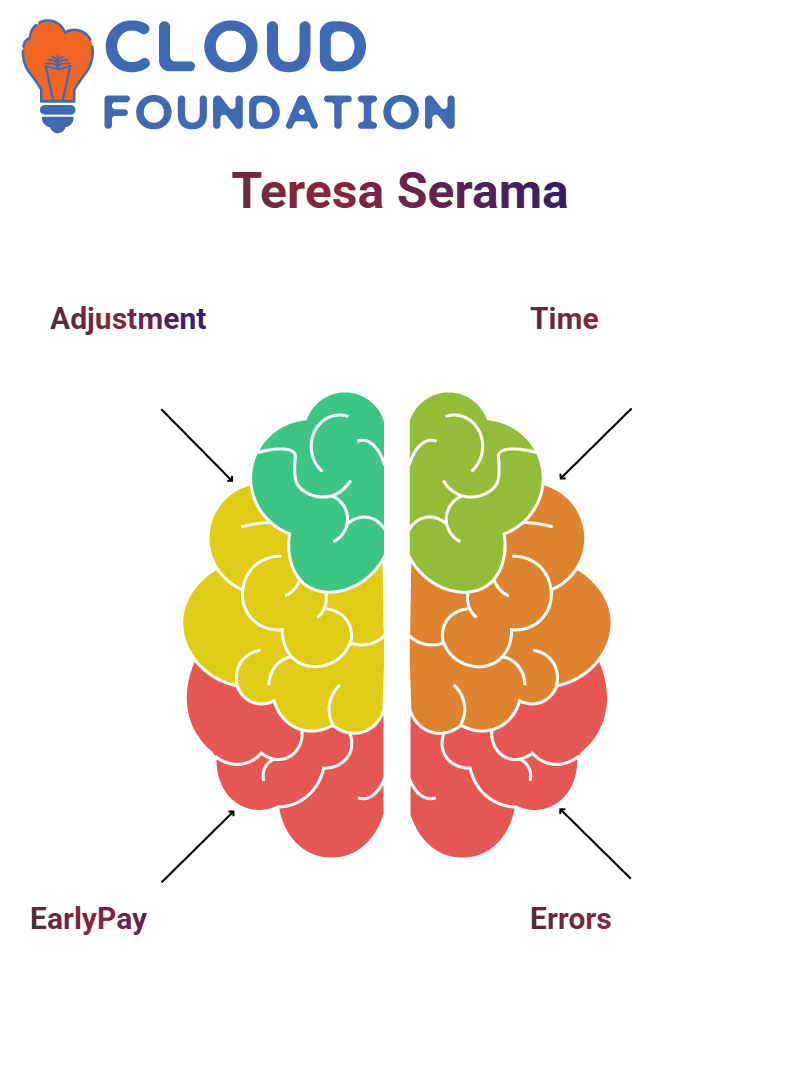

Handling Adjustments and Credit/Debit Notes

Real-world invoicing isn’t always straightforward—sometimes adjustments are needed. Teresa Serama supports:

Debit notes for increasing invoice amounts (e.g., raising an invoice from $5,000 to $6,000).

Credit notes for reducing amounts (e.g., supplier delivers fewer goods than expected).

These adjustments are linked to the original invoice, ensuring transparent and traceable records.

Early Payment Discounts

The tool also supports early payment options. For instance, a supplier may offer a 4% discount if payment is made in advance.

While testing this feature requires verification, it’s a valuable function for companies seeking to optimise their cash flow.

While testing this feature requires verification, it’s a valuable function for companies seeking to optimise their cash flow.

Benefits of Using Teresa Serama in Workday

Time Savings – Copying invoices instead of creating them from scratch reduces repetitive work.

Error Reduction – Control total validation prevents mismatched entries.

Transparency – Linked invoices, credit notes, and conversion rates provide a clear audit trail.

Scalability – The ability to handle multiple invoices, suppliers, and currencies makes it suitable for growing businesses.

Financial Optimisation – Features like early payment discounts and settlement runs improve working capital management.

Streamlining the Purchase Order Process: From Creation to Compliance

In any growing business, purchase orders (POs) are a cornerstone of the procurement process.

They not only formalise the intent to buy but also ensure that every purchase is traceable, approved, and compliant with company policies.

A recent discussion highlighted the practical steps, challenges, and controls involved in creating and managing purchase orders, using a real-world example led by Teresa Serano, an immediate entry specialist.

The Purchase Order Lifecycle in Workday

A purchase order typically follows 5 to 7 structured steps. While the exact flow may vary across organisations, the standard process includes:

Creation of the Purchase Order – Initiated by an authorised specialist like Teresa Serano.

Approval Process – Ensures oversight and compliance.

Supplier Engagement – Sharing the PO with suppliers for acknowledgement.

Receipt of Goods/Services – Validating that the supplier delivers as promised.

Invoice Matching – Checking invoices against the PO and receipt.

Compliance Checks – Security and process validations to prevent fraud.

Closure – Marking the PO as fulfilled and recording it for future audits.

Purchase Order Types and Task Management in Workday

Purchase orders (POs) are categorised according to their own classifications. For example, some organisations may define a master PO type for recurring vendor engagements, while others may create one-time purchase POs for ad-hoc needs.

The process of managing requisitions and POs involves two key actions:

Initiation – Raising and submitting the requisition.

Closure – Completing the purchase cycle once goods are delivered and payment is made.

To avoid delays and inefficiencies, businesses often integrate parallel workflows rather than creating repetitive tasks. This flexibility enables teams to manage multiple requisitions simultaneously, reducing their dependency on manual intervention.

Creating a Purchase Order in Workday

The PO can be generated in different ways:

Starting from scratch (a blank PO).

Copying an existing order.

Creating from a supplier contract.

The system also allows businesses to categorise orders based on goods, services, or project service lines. Key details, including supplier address, shipping location, and tax codes, are provided to ensure accuracy and completeness.

In the example, the company chose to procure 10 items of office supplies, each priced at $100, with delivery to New York. This demonstrates how even routine purchases require proper documentation and controls.

Workday Online Training

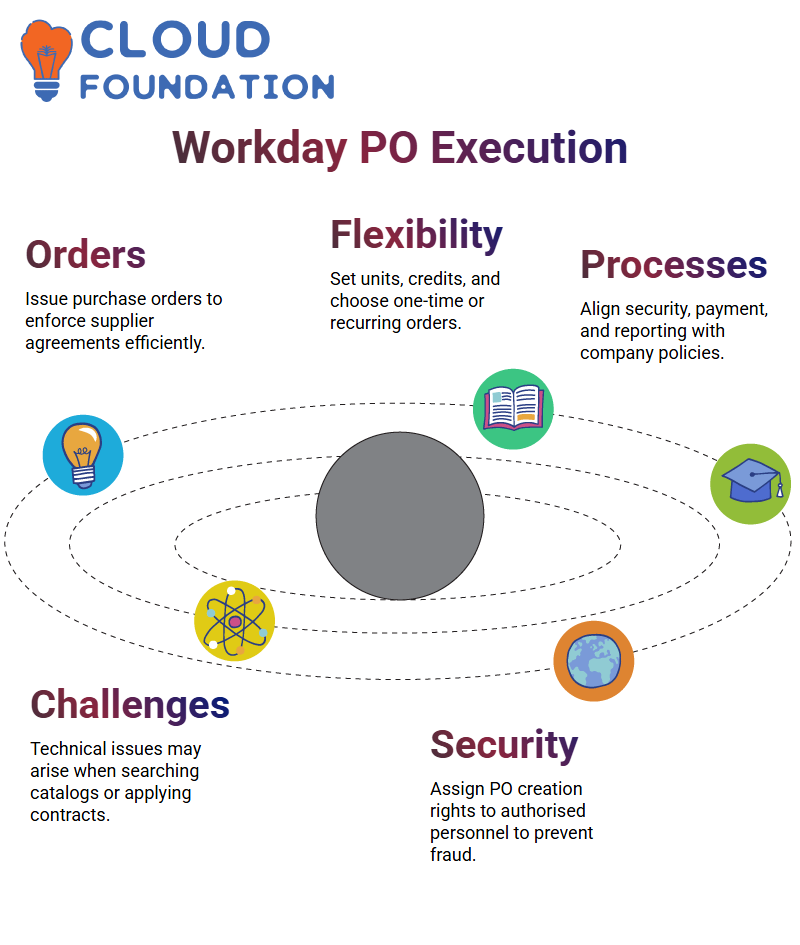

Workday Purchase Orders: Executing Supplier Agreements

Once a contract is in place, the next step is generating a purchase order (PO). The PO serves as the formal request for goods or services, binding the supplier to deliver as agreed upon.

Highlights of the PO process include:

Direct creation without approval steps (in some systems).

Flexibility in ordering: Businesses can set the number of units, credits, or even choose between one-time or recurring orders.

Business process considerations: Security, payment workflows, and reporting must align with company policies.

System challenges: Teams may encounter technical issues when searching catalogues or applying supplier contracts, highlighting the importance of a robust procurement system.

System challenges: Teams may encounter technical issues when searching catalogues or applying supplier contracts, highlighting the importance of a robust procurement system.

A well-defined PO process ensures a smooth transition from contract negotiation to actual purchase, minimising errors and delays.

Workday Security and Control Measures

One notable concern raised in the discussion was security. To protect the company’s reputation and financial accuracy, businesses often assign PO creation rights to a specific role. In this case, access was assigned to Teresa Serano.

Additionally, custom malicious controls and proxy measures were highlighted as essential safeguards. By proxying under Teresa’s role, the system ensures that only authorised personnel create purchase orders, reducing the risk of fraudulent entries.

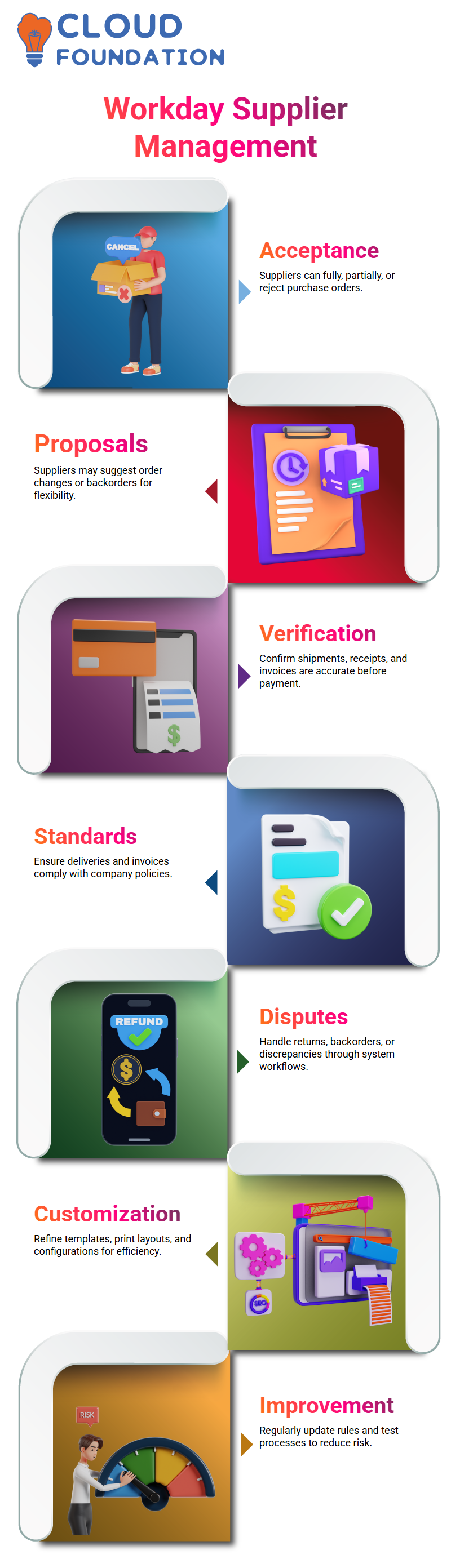

Supplier Interaction and Acknowledgement in Workday

Once issued, the supplier receives a PDF copy of the PO. At this stage, the supplier has three possible responses:

Fully accept – Deliver all items as requested.

Partially accept – Deliver some items (e.g., 5 out of 10).

Reject – Decline the order.

Suppliers can also propose changes, backorder items, or reject economic exceptions. This flexibility ensures smoother collaboration, keeping all changes visible within the system and allowing for seamless updates.

Validation and Compliance in Workday

After suppliers acknowledge the PO, businesses must validate deliveries. This involves:

Checking ship notices.

Reviewing receipts for completeness.

Confirming invoice accuracy before payment.

If discrepancies arise—such as missing items or incorrect invoice details—the system provides workflows for handling returns, backorders, or dispute resolution.

Continuous Improvement in Workday

The conversation emphasised that POs aren’t just documents—they are living processes that can evolve with system upgrades and company needs. Teams are encouraged to:

Explore advanced configurations.

Customise print layouts and templates.

Conduct negative testing to uncover system weaknesses.

Define clear rules and guidelines to avoid ambiguity.

Even small changes, such as refining tax codes or adjusting supplier compliance checks, can significantly improve efficiency and reduce risk.

Workday Course Price

Vinitha Indhukuri

Author