What is SAP EWM | SAP EWM Modules

Welcome to SAP EWM Blog, where you will learn more about utilizing alternatives to conventional warehouses to achieve previously unseen efficiencies, adaptabilities, and agility levels.

Start streamlining your warehouse processes immediately, and check our EWM blog regularly to stay abreast for helpful advice and updates on SAP EWM

SAP EWM Overview, Introduction to SAP EWM

Organizations using SAP EWM benefit from improved manual stock management, superior resource allocation and automated processing and transportation solutions.

Furthermore, its storage facility management improves worldwide, which benefits inventory control management, distribution planning and cost reduction efforts.

Extended Warehouse Management’s primary capabilities are automatic materials handling, execution and routing as well as warehouse labor management improved supply chain visibility.

Data structures, cross-warehouse determination, SAP EWM handling unit, monitoring stock dispatch activity, route ID assignment and sequential ID assignment are among other innovations introduced into today’s software programs for managing warehouse activity and an organization’s warehousing management systems.

SAP Enterprise Work Management can integrate SAP CRM, ERP, CWM and GRC and industry-specific toolkits for more efficient logistics and supply chain unit in SAP EWM activities.

By unifying all related processes and procedures organizations can streamline complex logistics activities with greater speed.

What Is SAP EWM?

SAP Extended Warehouse Management does not specialize in managing process-oriented tasks such as procuring raw materials from suppliers and transporting them directly to production units, like SAP Manufacturing Planning does; rather it simply moves warehouse items.

EWM can also facilitate communication of warehouse volume information to material receipts and employee communications to human resource modules.

Stores Management provides EWM for retail sales on a smaller scale. The Warehouse Management System comprises five processes, such as Warehouse Process Framework, Physical Inventory Counting, Strategic Decisions, Material Flow and Physical Storage.

What is EWM in SAP?

SAP EWM automates warehouses without third-party integration, as well as Automating and Integrating Warehouse Procedures for real-time capture.

Warehouse automation requires capabilities like product location and physical inventory Capabilities EWM provides thanks to its integration with inventory/order management software.

Packaging/deconsolidation, load management and labor administration also play a part in its implementation.

SAP EWM integrates ERP but doesn’t handle goods receipts or issues directly; installing, training and operating the system efficiently are the keys to its successful use.

Integrating warehouse operations with sales or inventory management evaluates strategic goods flows while creating timebound delivery procedures and logistics procedures for timely deliveries and logistics solutions.

Large companies with multiple locations and global clients take advantage of it.

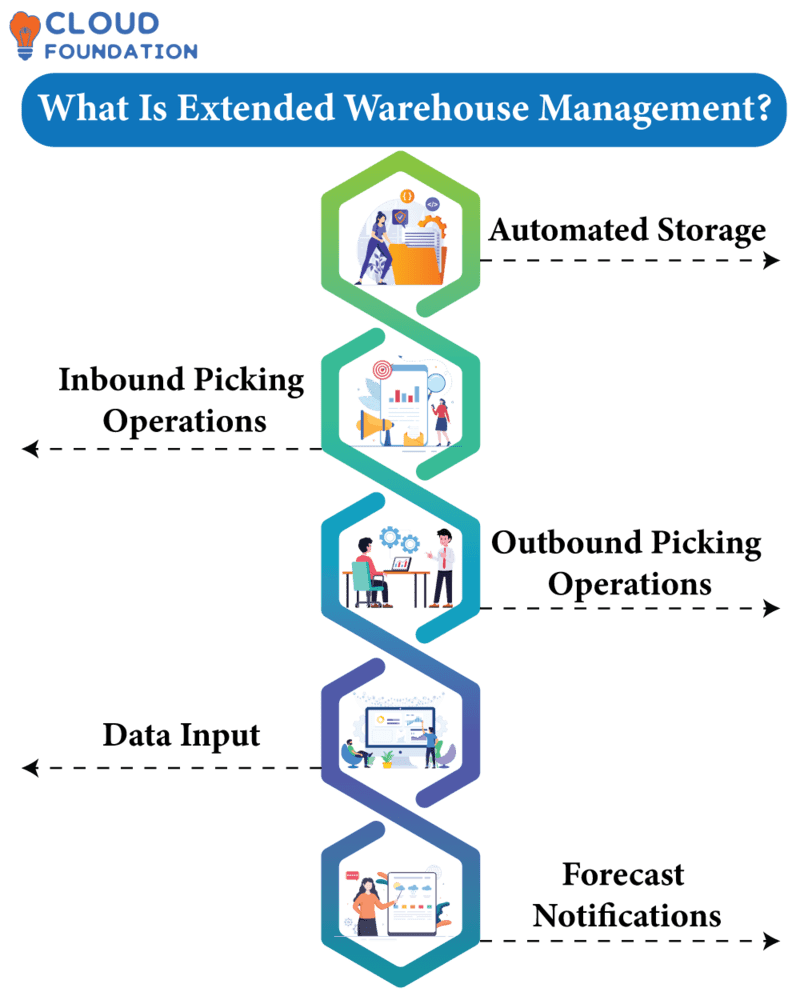

What Is Extended Warehouse Management?

SAP EWM tracks product issuance, receipt, picking, loading and unloading in Warehouse Management.

Automation includes automated storage, SAP EWM inbound Process Flow or Inbound Picking Operations, SAP EWM Outbound Process Flow or outbound picking operations, data input and forecast notifications.

Existing warehouse management programs lacked the data SAP EWM required to automate storage activities.

SAP EWM enhances SAP ERP’s storage management functionality with automated features that enhance its safety.

All warehouse storage processes can be planned, monitored and managed using customized user interfaces that compile all relevant information about activities across warehouse units into one consolidated place for planning.

Products may be assigned warehouse locations and tracked in real-time.

SAP EWM helps warehouse staff plan activities efficiently using dynamic global sources that offer up-to-the minute information. EWM makes incorporating new business processes quickly easy.

Workers are given options while EWM supervises your facility with ease.

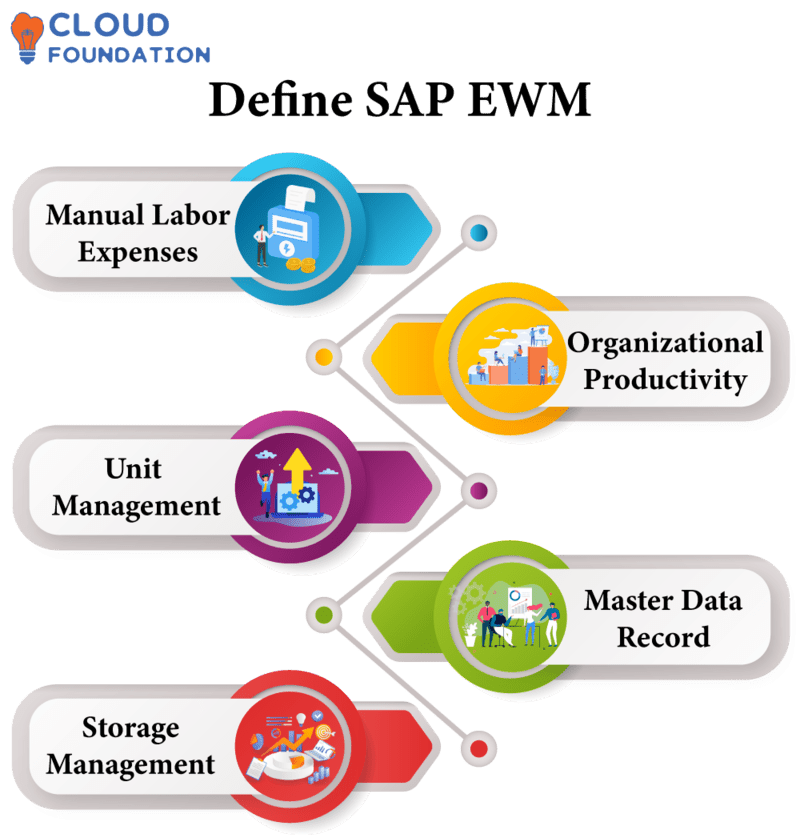

SAP EWM definition or Define SAP EWM or EWM SAP Meaning

Utilizing EWM reduces organizational expenses such as Manual Labor Expenses and Organizational Productivity Loss while streamlining resource, inventory and cash flow management systems optimizing warehouse inventories increases income maximization.

Product focused trade tactics such as SAP EWM stock keeping unit management, inventory movement and item physical qualities and quality specific properties are at the core of product innovation.

Storage methods range from warehouses, manufacturing racks, and decentralized storage without stock.

Each provides you with visibility into product placement, amount, and status throughout loading and unloading operations.

SAP EWM data is stored in a Master Data Record (MDR), making it accessible for employees, end clients, executives and managers to review at various stages in the supply chain.

The (KPI) Key Performance Indicators reports and visualizations help put this information into context based on time, product variety pricing and quality considerations.

Consumers that come through during product sampling typically explore more extensive retail systems like storage or customer specific material handling systems.

Bullet Mining certain client or customer groups requires you to assess your warehouse, system and inventory needs in terms of both customer group needs as well as storage management needs. If it fits, take note of this consideration for control in terms of storage management systems.

However, you should understand that classifying, storing and transporting inventory items are complex processes SAP EWM was built specifically to handle them efficiently globally.

What does SAP EWM do, and what is SAP EWM used for?

Any company storing goods, supplies and stock in warehouse or storage facility requires SAP Extended Warehouse Management (EWM).

Implementing EWM improves efficiency, customer service levels and overall handling costs while simultaneously increasing WM performance and improving warehouse management efficiencies.

An effective Warehouse Management system (WMS) gives an executive an accurate picture of stock status, warehouse movement and meeting customer demands cost effectively.

Most small firms cannot manage warehouse management effectively, which has serious ramifications on production, transportation and supply chain management.

Warehouse management works best in larger companies with complex storage operations and plenty of merchandise.

ERP and materials management users are best placed to implement warehouse management solutions.

Use of SAP EWM

Warehouse management could potentially add layers to daily operations whereas for detailed Storage Planning there may not be the need to monitor goods through to shipping or receiving.

Supply for Inventory and need-based planning combine the benefits of Warehouse Management into their practical benefits, which is why so many major organizations incorporate SAP’s EWM module into their Core System for seamless integration into everything else they do.

EWM systems have evolved since ERP and Supply chain management systems this provides documentation, planning support, and an ad hoc warehouse stock location system to keep warehouse inventories at optimal levels.

Of course, those familiar with warehouse management understand the necessity of adequate storage to achieve success, with cost-cutting being accomplished using unit pricing data or sales volumes as strategies to successfully operate warehouses on minimal budget.

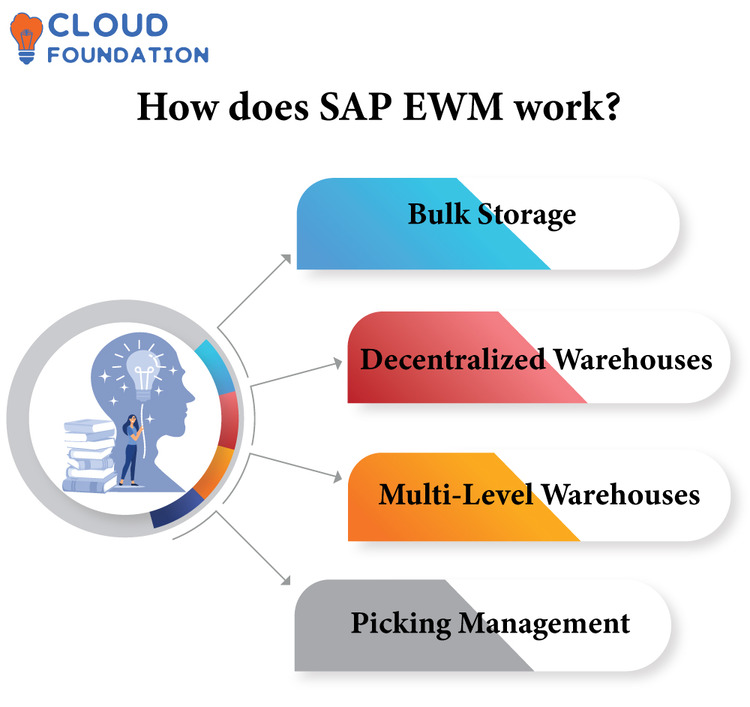

How does SAP EWM work?

Warehouse management software supports bulk storage, decentralized warehouses and multi-level warehouses. Picking management can also be employed flexibly or standalone as necessary.

It offering stock management, material flow tracking, document storage management and RFM prediction as core tasks for these three-tier Windows or Linux systems.

SAP EWM integrates seamlessly with JDA, Pro Shines Goodware and Jd warehousing systems global supply chain management often uses these.

Furthermore, WMS, Transhub GDS or Ats can all manage shipping or transportation and may be linked with SAP EWM for seamless management and control.

Why SAP EWM, and what are the benefits of SAP EWM?

SAP EWM’s primary aim is the efficient sale and management of inventory across various locations and distribution centers, to maximize sales figures while creating optimal stock levels at every step along the supply chain an optimal inventory at each stage and location is what sets this system apart from others!!

Management and storage in warehouses involve overseeing inventory to create an organized database that includes materials that need to be located.

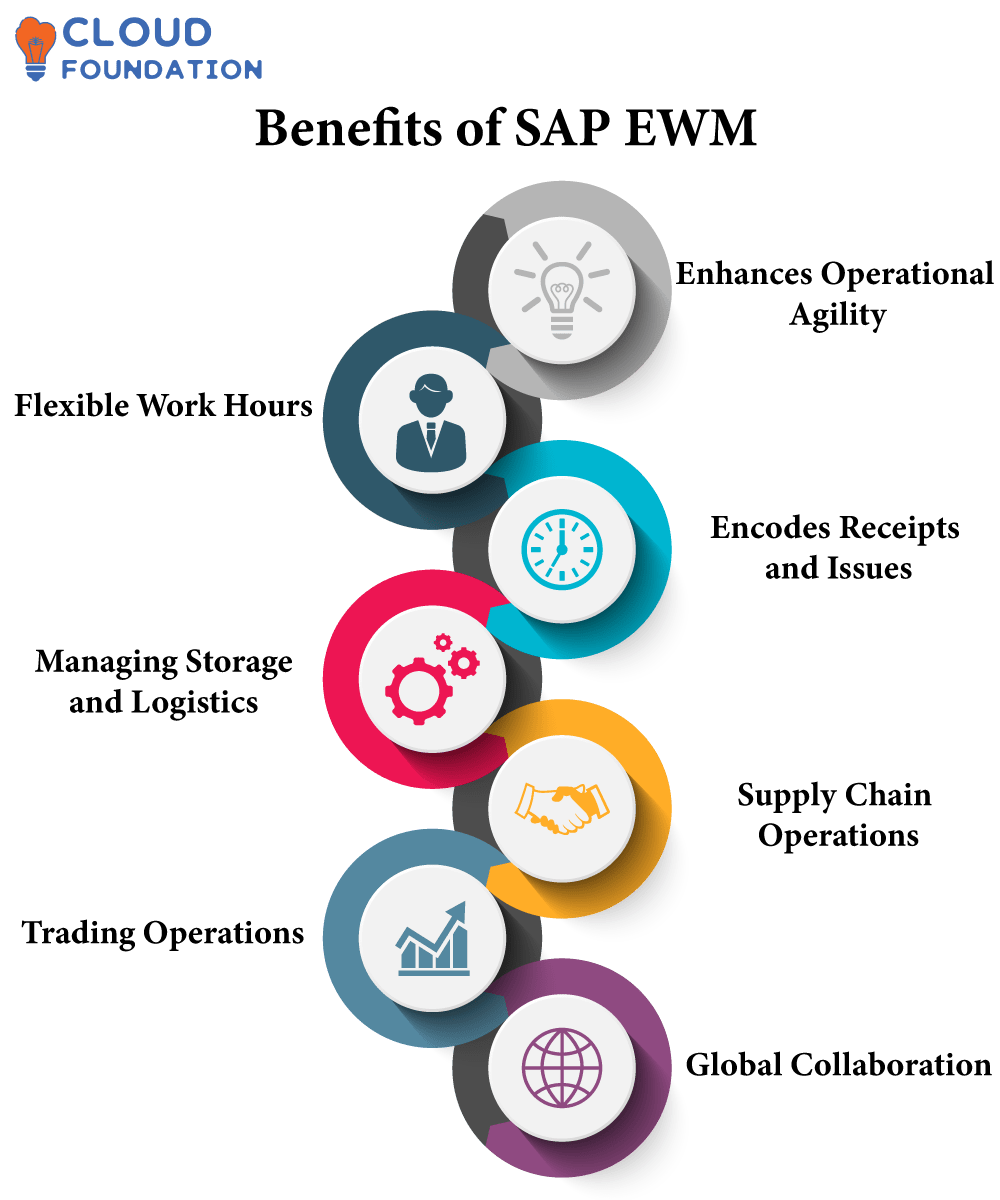

Benefits of SAP EWM

Enhances Operational Agility

WMS helps warehouse managers adapt quickly to shifting client expectations and e-commerce trends, which provides additional operational agility. EWM seamlessly integrates warehouse management and distribution services for real-time visibility of real data and can raise limits based on resource constraints.

Flexible Work Hours

These data and analytics enable warehouse managers to access human resource requirements and adjust working hours as necessary. SAP EWM gives them real-time data visibility that enhances their ability to improve it further.

Encodes Receipts and Issues

Goods receipt and issue encodings manage movement between goods issued and receivedt their associated receipt encoding must also be linked. REST Web Services provide event-triggered encodings which provide this important data that helps managers efficiently oversee staff and operations.

Companies can reduce waste and other expenses by making smart use of resources on time, like SAP EWM which secures goods and warehouse supplies.

Managing storage and logistics communications efficiently

Warehouse procedures and job tasks give a 360-degree overview of goods in storage. The data analyses from SAP EWM allow managers to make more informed decisions like productivity, quality and customer happiness all increase as a result of using it.

Cut Cost in Supply Chain Operations

Supply chain expenses can be decreased through better warehouse management, leading to reduced manufacturing costs and inefficiency.

Enables vertical and horizontal trading operations

Vertical trade in e-commerce refers to the exchange of items between firms while flat trade refers to intermediate storage space between these firms. Vertical trading reduces supply chain costs whilst flat trading serves intermediate storage needs.

Enables Global Collaboration

In addition, this program may connect to other SAP ERP programs to exchange data across global enterprises.

Advantages of SAP EWM

SAP EWM helps manage hazardous items reducing transportation.

SAP EWM enhances cost visibility while simultaneously Decreasing Expenses and Increasing Profitability, through an RFM tool which estimates inventory needs and expenses accurately.

Furthermore, its simplified procedures manage multiple activities across departments with lower operating expenses while increasing efficiency thereby decreasing costs while simultaneously increasing productivity.

SAP EWM reduces IT costs by seamlessly integrating with SAP ERP, which reduces development costs of warehouse management system development.

Furthermore, consumers can track logistical responsibility and delivery status. A better customer experience increases retention.

SAP EWM’s RFM product enables warehouse managers to make legally compliant decisions that comply with customer-oriented practices while staying compliant with government standards, making the warehouse process customer friendly as well as legal.

SAP EWM’s RFM product provides organizations with a solution for efficiently managing inventory and delivery to increase customer experience and satisfaction, improving both happiness and service quality.

Furthermore, this feature streamlines selection, packing and shipping as well as improving warehouse transparency in an effective and straightforward manner.

What is SAP EWM software, and how to use SAP EWM?

EWM Software features two unique designs such as Sap EWM Warehouse Processing and SAP EWM warehouse Structure.

Vehicles must be designed specifically to deliver stored items to stations supplied with them; product movements from warehouse to warehouse; stock data transfer and material movement must all be included for this purpose.

Multiple product structures such as packaging and non-packaged versions may be utilized to ensure products have all of their details for storage, processing and use.

After conducting an analysis on different system types, companies and institutions in manufacturing industries such as materials handling, storage, retail chains warehouses and C-stores for efficient order execution were won over by this software’s high degree of transparency and upward trend that is tailored to individual needs.

EWM solutions assist warehouses by customizing, purchasing modules, designing their processes efficiently, and real-time display of data.

Users of EWM can collaborate simultaneously. EWM data are typically pictorial users may enter data through SAP ERP data entry system for seamless real-time collaboration and shuttle communications.

EWM can be divided logically into goods reception monitoring, prior storage monitoring, goods issuance tracking and after storage monitoring each area requires different applications that do not just target one aspect.

SAP EWM for Dummies provides an essential guide that can assist those unfamiliar with SAP EWM in understanding its fundamentals, features and functionality.

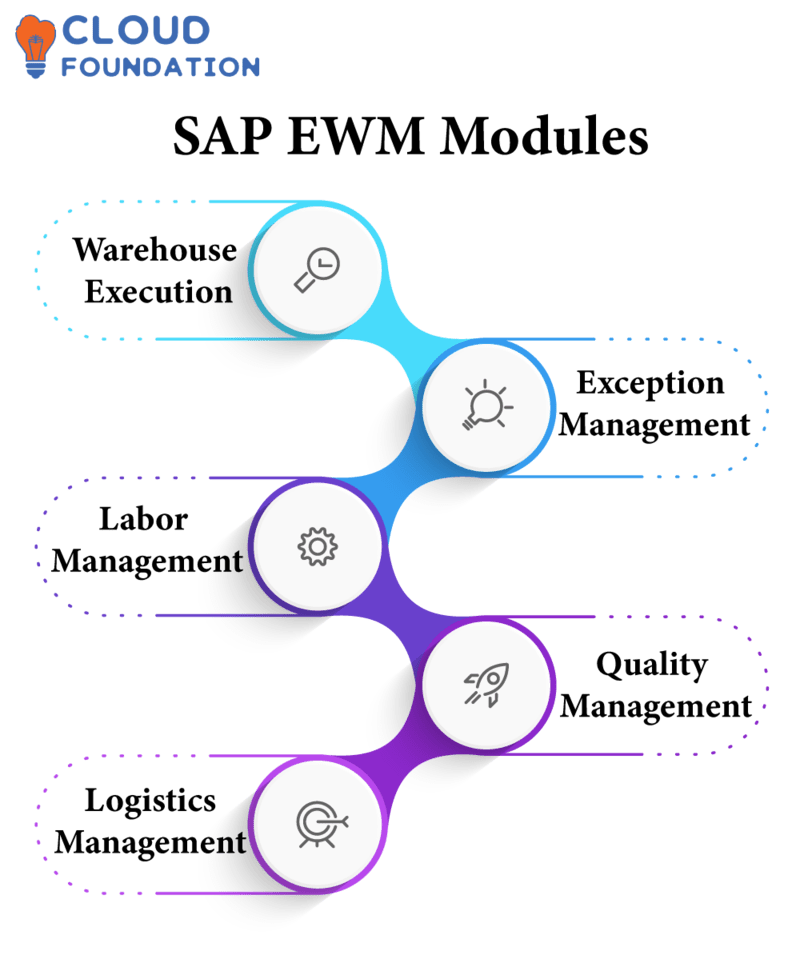

SAP EWM Modules

Warehouse execution, exception management, labor management, quality management and logistics management are the core features of this system. The warehouse manager serves as the gateway between ERP software and expanded warehouse management solutions.

Warehouse execution application manages this system and performs picking routing and work planning functions.

SAP EWM exception management tracks and manages deviations from pre-planned goods movements, providing warehouse managers and branch managers with exception as products enter and depart warehouse facilities.

Warehouse managers, supervisors and personnel benefit from quality control measures involving durability, fitness and sustainability that guarantee 100% quality items.

What are the best ways to learn SAP EWM?

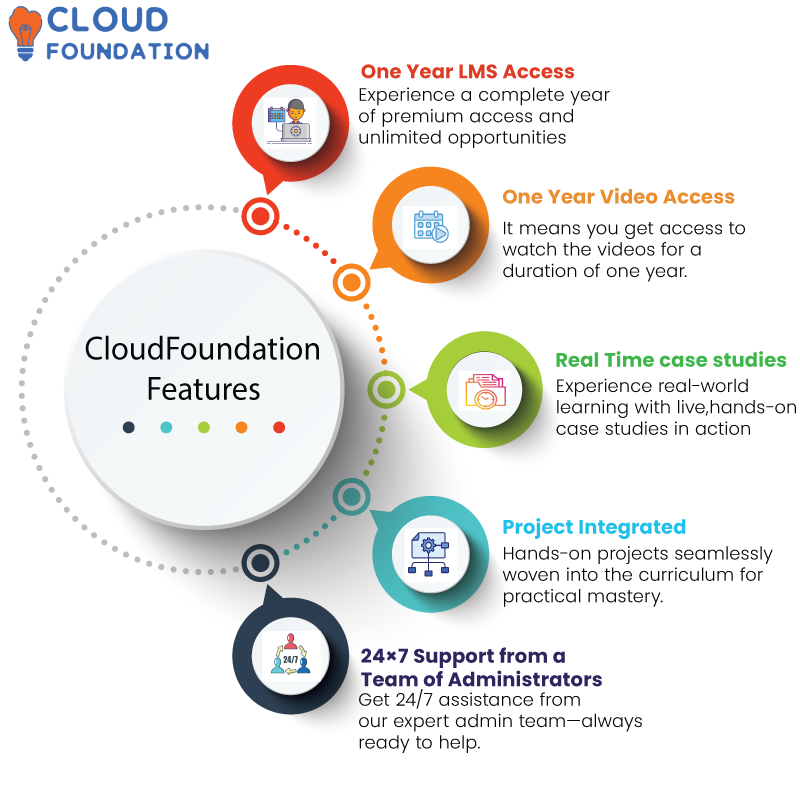

Are You Seeking an Upgrade and Increase in Understanding of SAP EWM? Take the SAP EWM Course and for optimal SAP EWM learning experience, CloudFoundation offers several courses and SAP EWM videos dedicated to SAP Warehouse Management (EWM).

Furthermore, the blog contains extensive knowledge regarding EWM.

Our articles feature insight from subject matter experts and experienced SAP EWM users alike offering best practices and methods to increase warehouse productivity.

Divya

Author