SAP EWM Tutorial for Beginners

Are You Planning on Implementing SAP EWM for Warehouse Management? It will make managing inventory and daily operations much more streamlined for those responsible.

SAP EWM Meaning

Extended Warehouse management (EWM) encompasses every area within a warehouse storage areas, loading/unloading sites and process areas while Warehouse Order Management (WOM) allows products and work-in-progress to enter this complex system seamlessly.

Warehouse facilities typically consist of separate areas dedicated to storage rooms, work in progress areas, shipping and receiving.

EWM helps companies that depend on Inventory Dependent Businesses organize their items. EWM integrates product supply as well as other functions. Furthermore, this software supports multiple parts in this situation.

Extended Warehouse Management can keep track of every item. By placing all physical divisions, operations, workplaces and responsibilities onto an interactive map in EWM warehouse, all items can be kept track of easily and conveniently.

SAP EWM yard management

SAP EWM Yard Management was designed to address the Warehouse Management Needs of various businesses. Sap EWM Yard Management ensures the Optimal Inventory is used at competitive pricing in order to increase manufacturing processes for finished goods and raw materials.

SAP EWM Yard Management software automatically monitors inventory or product planning options that offer optimal benefit, further increasing corporate productivity. In addition,SAP EWM Yard Management features which may enhance productivity within organizations.

SAP EWM Yard Management suite can only be utilized by companies engaged in production, distribution, transporting and managing inventory.

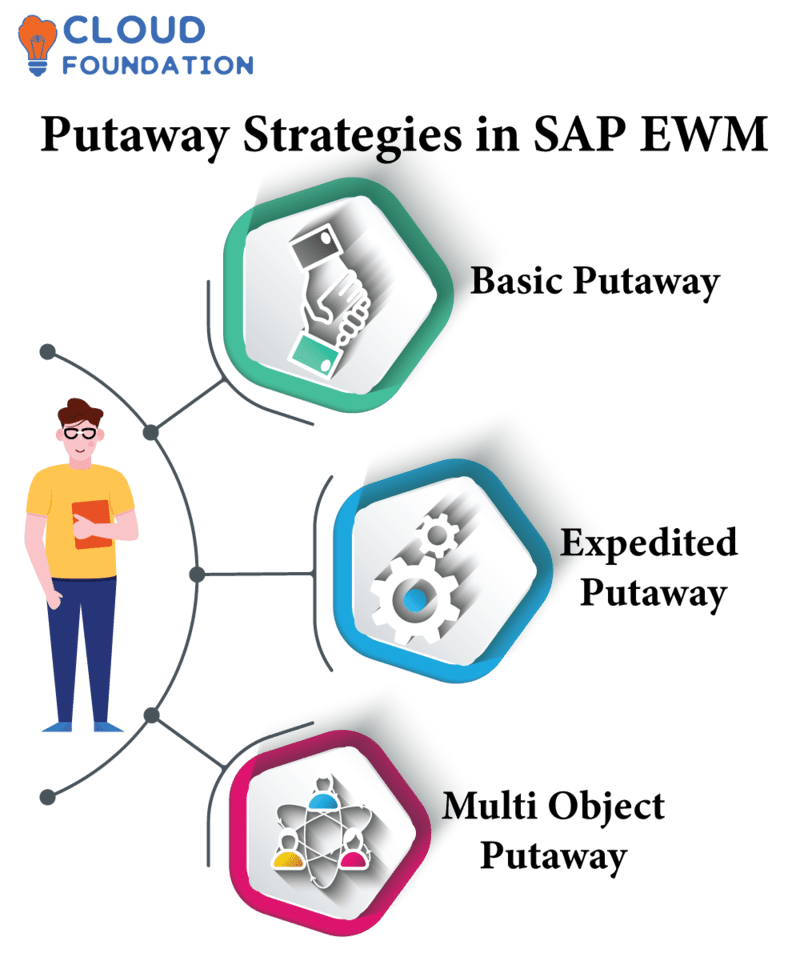

Putaway Strategies in SAP EWM

EWM may not be necessary for unsalable or processed commodities; its putaway strategies in SAP EWM provide stockroom product putaway and Pickaway orders. putaway strategies can even include targeting storage bins with putaway approaches as targets.

Putaway techniques are applicable globally across warehouses or product types. Methodologies may take into account infrastructures like pick route managers, work center responsible for putaway, priority lists or prioritized lists as criteria for putaway.

Putaway Strategies for SAP EWM are:

Basic Putaway

Expedited Putaway

Multi Object Putaway

Putaway strategies can encompass multiple SAP EWM trading periods one bin can have its own putaway approach. Putaway activities can use one or more putaway strategies this may involve items, storage bins, categories of storage bins, work centers for putaway operations and the establishment of priority lists by putaway strategies.

Putaway strategies must include product type, storage bin size and the first-in, first-out rule when choosing and conducting putaways.

Tips for selecting Putaway techniques from SAP EWM include warehouse wide Putaway techniques as well as specific bin types within EWM Work Center and warehouse putaways.

Warehouse-wide or bin-type FIFO techniques could be chosen. When stock piling products with multiple identical storage bins, these techniques would likely prove most suitable.

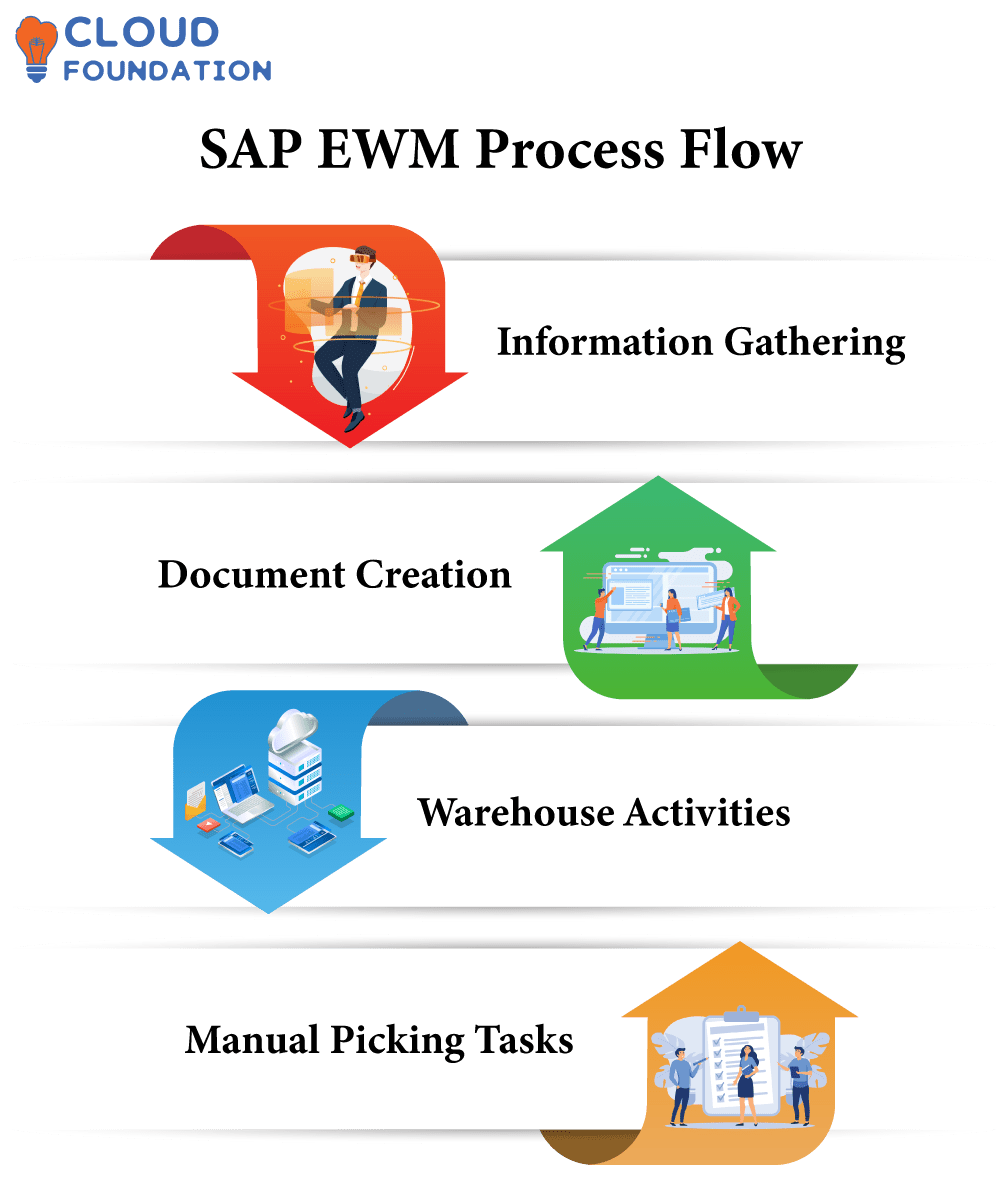

SAP EWM Process Flow

EWM process flow for SAP displays how a master item should move through various Work Centers (WC) before physical inventorying occurs.

EWM’s visual display shows work centers with products in leading lights as well as information such as warehouse bill of materials, unit type location and serial numbers in leading lights for physical inventorying purposes.

An SAP Extended Warehouse Management process flow refers to a series of activities which change or update a Stock Keeping Unit (SKU), master item or resultant or replenishment keeps or deconsolidate and remove it.

Each SAP EWM Process flow can be broken into four steps that include information gathering, document creation, warehouse activities, manual picking tasks. Multiple flows can be connected together via link nodes for increased flexibility.

SAP EWM Displays the Process Flow Number When You Create One.

SAP EWM Inbound Process

Customize inbound deliveries from various vendors and special deliveries easily by setting processing types (standard/push the delivery for purchase orders; special/pulled for packing lists) and methods of operation (Manual or Automatic).

In this way you can ensure delivery from each one according to their unique processing type/method/process method automatically identified for inbound operations.

Purchase Order Headers initiate inbound processes. They allow you to track inbound deliveries against an order number or source and even confirm it automatically for greater efficiency in facilitating push delivery.

Inbound Process Includes Inspection and Putaway Processes. Each phase may consist of packing products or creating packing lists; additionally, this process generates packing slips, warehouse jobs and transport requests to retrieve product from SAP EWM storage bins.

By organizing process steps at different work centers and shipping products between them during each process step, it becomes easy to choose one work center as the hub for all phases of production.

Process steps in warehouse actions require multiple steps, with these executed automatically by the system instead of manually.

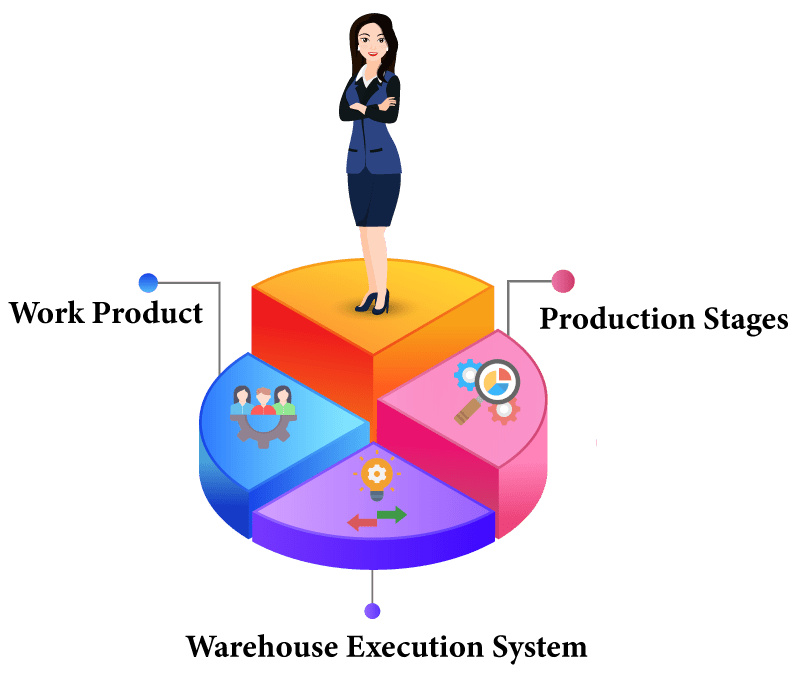

SAP EWM Outbound Process

Within SAP EWM’s Outbound process is used when picking, sorting and packing are not performed at an outbound transshipment node.

Temporary storage at this staging point is known as warehouse execution system outbound storage point while this also denotes physical area with WX system outbound temporary storage at segment nodes; outbound processes may also be defined during inbound processing.

Route physical units to or from an outgoing process for adjustment; this quantity adjustment follows with physical team in an export procedure.

Outbound operations may create a Work Product (WP), Production Stages (PS), Ship Only ItemsOutbound processes (OP) separate physical units into routes whose amounts change across several stages, automated or semi-automated solutions exist as well.

SAP EWM Once goods transfer takes place, SAP ERP posts goods movements accordingly. You must enter all information for earning, supplying and moving transferred items as per outbound process of SAP EWM warehouse plant.

Every outbound process activity and good ID triggers a goods movement, goods arrive for receipting at reception and depart on issue in accordance with goods receipt/issuance processes, respectively.

SCIM (System for Cross-domain Identity Management) allows outbound processing between facilities in either a supplier warehouse or shared warehouse, although general outbound processing can only take place at supplier facilities.

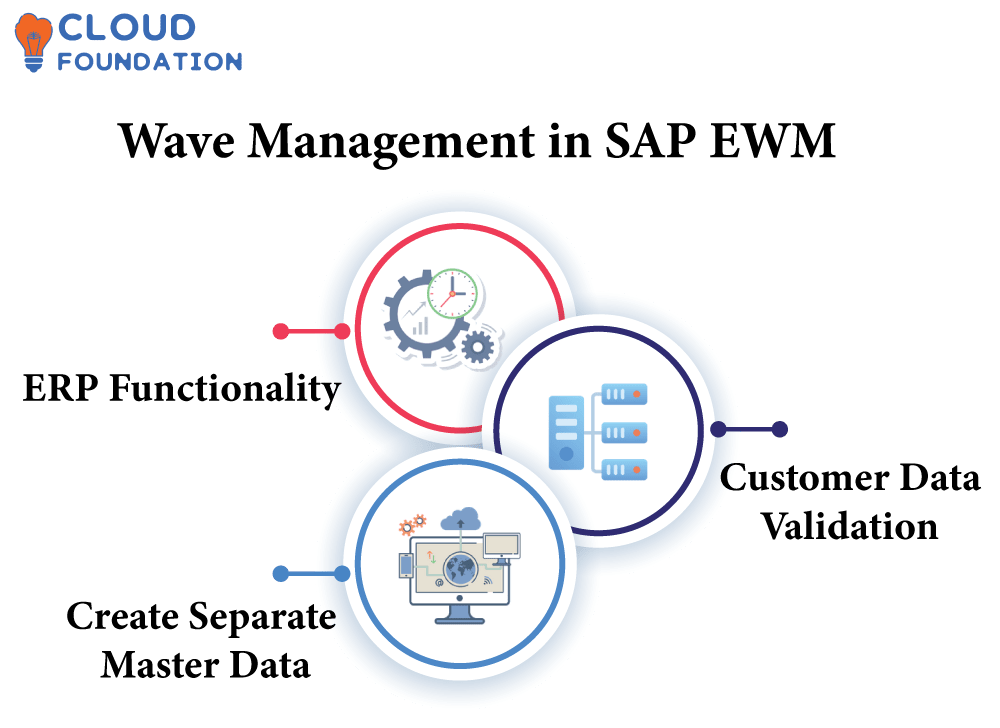

Wave Management in SAP EWM

Wave management allows you to produce personalized collection papers for consumers and deliver them to various distribution centers or transportation units within SAP EWM.

Wave management makes use of ERP functionality.

Display distribution documents by customer or product order to display in an exception message for customer or product orders, followed by guidelines for assigning goods to wave.

Apply wave nodes to encode business logic such as customer data validation in customer interfaces.

To meet resolution specification criteria, create separate master data.

Utilize wave management tools in SAP EWM.

Activity Area in SAP EWM

Each warehouse provides various activity spaces designed for specific uses.

SAP EWM Picking Process Area: SAP EWM warehouse associates use this area during picking procedures; machines use this section of SAP EWM’s picking machine during their picking procedure to pick products after creating pick procedures for assembled products, master items and variants.

SAP EWM Putaway Process Area: Used to store product palletization.

Strategically planning activities requires selecting an activity area. Each activity requires its own space; product arranging methods require at least one putaway process while packing needs packing operations for instance during warehouse development.

Before customising, be sure to thoroughly assess your activity areas. Without creating a warehouse first, there may be delays in execution unless an activity area can be changed accordingly use the default warehouse creation as an effective solution here.

New products enter an EWM activity area while its product master controls access privileges for warehouse workers to select products based on access privileges and enter them in procedures automatically, tracking any recent put procedures while assuring you use of correct one.

Each activity area begins by creating an SAP EWM task in its internal system, which displays task, unit information and labor slots on screen for display and alert users if completed tasks have not been accomplished within timeframe. Warehouse manufacturing creates tasks in activity areas while labor takes precedence on set dates.

Replenishment in SAP EWM

Replenishment in SAP EWM can be defined as the Setting the processing time of products, forms or packing unit documents to zero in Extended Warehouse Management (EWM) allows them to be processed any time irrespective of storage or processing times.

The system utilizes the stock quantity you enter in the Product Master Data and Warehouse Management Master Data to calculate an exact replenishment quantity at different storage times, taking into account its current inventory value. It then selects suitable replenishment items accordingly and orders them.

Maximum Stock Replenishment Aim at replenishing current stocks to an amount equal or exceeding your storage time stock capacity, without going below this number.

Add a storage bin master or assigned storage bin with warehouse-specific use restrictions into SAP EWM selection logic for tasking selection purposes. Your working period and processing activity at various times are controlled with this Master Data Storage.

An assigned storage bin serves as the confinement area for processing documents that restrict their use to products during their current working period, providing that their usage restriction fits in line with that of their processing document’s working timeframe.

Cross-Docking in SAP EWM

Through Cross-Docking, users are able to verify, prepare, stock, and release products throughout a warehouse storage space.

Advanced Cross-docking Worksheet allows users to designate storage bins, modify their statuses and activate Work Cycles for outbound bin substitution. You can trigger cross-docking cycles or outbound storage bin exchanges when desired.

When there are no suitable storage bins in the cross-docking worksheet or no suitable interim storage quantities for one particular storage bin that require cross-docking to take place, launch Cross-Docking under the Advanced tab of their warehouse assignment for that storage bin.

Here, you can identify storage bins eligible for cross-docking and manually initiate the procedure. This does not reflect stock levels or (outbound/inbound) product amounts they simply indicate potential cross-docking processes that could take place.

Atemporary storage bin substitution mechanism may be activated in response to products utilized. status would then change to “Interim Storage Quantity at Hand Expected, Starting Cross Docking”.

SAP Embedded EWM

This program makes it possible to manage and monitor the warehouse system effectively and efficiently, including quantities, stock levels and data transfer to SAP ERP or CRM. Furthermore, full visibility into warehouse operations enables correction of procedures as necessary.

Integrated business processes provide effective oversight for warehouse activities. SAP Screen Integration makes integration between SAP EWM and other apps possible, and post-delivery data to either SAP CRM or ERP for various reports.

Reduce inventory and business process costs while simultaneously improving decision-making speed and effectiveness.

SAP EWM’s supervisory system stores employee and machine reservations. People can then oversee machines.

Warehouse tasks involve numerous products. These may include storage, receiving/outgoing processing, quality assurance inspection, quality management processes and more. SAP EWM automates real-time work task management for optimal efficiency.

You can see who or what machines are performing various activities; what stock there is; where difficulties have arisen and more. Close a task at multiple workstations so a person or computer can check its status at any time.

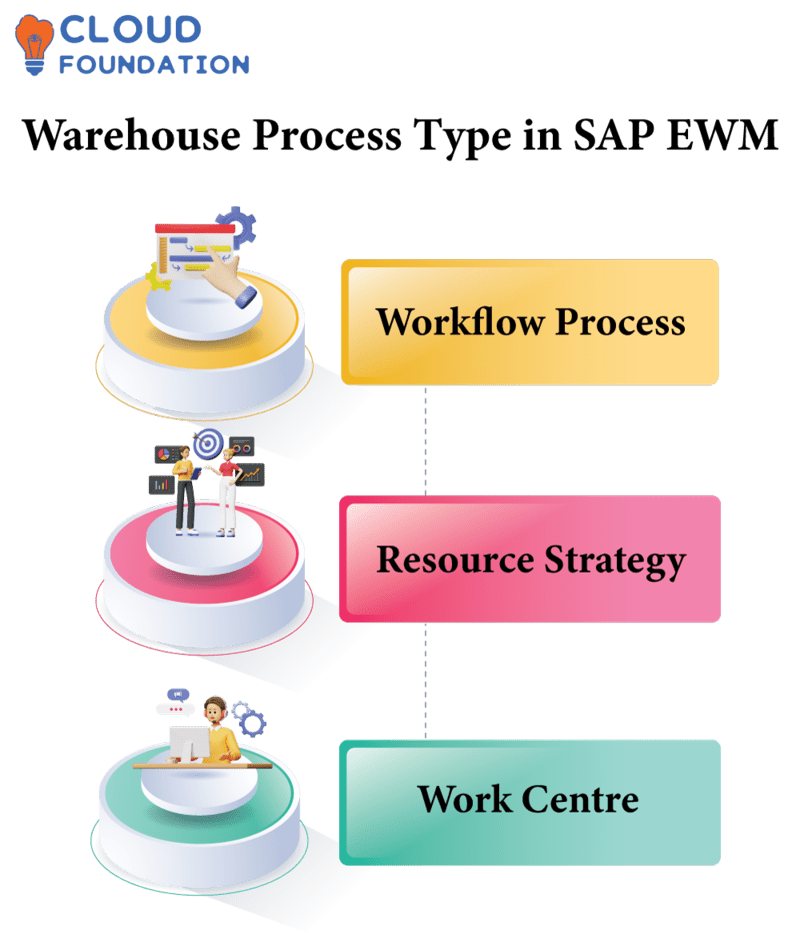

Warehouse Process Type in SAP EWM

SAP EWM Warehouse Process Types allow SAP Extended Warehouse Management users to log warehouse activity on various equipment in warehouse facilities into ERP.

Activityand bin-based warehouse processes.

Bin-based warehouses allow warehouse workers to quickly retrieve SKUs (Stock Keeping Unit) from one central location. Warehouse workers process stuff directly out of storage bins. SAP EWM processes may either run independently, or can be linked together depending on product category.

Both warehouse operations require an established workflow process, resource strategy and Work Centre business process start-up plan in order to be effective.

Configure the Work Centre, establish a resource plan, and construct Warehouse Process steps. Each stage contains activities and process steps; before beginning each warehousing, step users must personalize each step to meet their particular requirements.

Warehouse employees initiate each process step with the use of warehouse tools. Employees report activity successes to warehouse management. Once processing has concluded, warehouse management procedures send notice that processing has concluded via SAP EWM batch transaction.

Feedback will inform if a previous process was completed successfully or the system assigned an activity to you. Warehouse process steps may be edited as needed and Phases can either remain active or be terminated as desired.

When employing these operations, you must also monitor physical inventory levels as well as tools & equipment usage rates, job schedules & job scheduling schedules in addition to managing physical equipment inventory levels & job schedules for proper operations monitoring.

WOCR in SAP EWM

The Warehouse Order Creation Rules (WOCR) controls physical items being received into the warehouse, such as: SAP ERP master data warehouse order creation in production or stock profile preparation instructions.

WOCR in SAP EWM changes quickly or require timely storage decisions; quick or time-sensitive warehousing orders exist and the system automatically selects their type according to production area or stock profile preparations; in turn these lead to warehouse orders with accompanying operations that need to take place simultaneously.

Warehouse management system tracks all activities conducted within its warehouse from order formation through delivery. Utilizing its status monitor and WOP (Warehouse Order Processing) or Warehouse Management work centers, this allows you to keep an eye on orders.

Physical Inventory in SAP EWM

Physical Inventory can be conducted either using a warehouse bin or packaging unit that features scales for weighing or counting items, and physical inventory may take place at any point during any shift, period of work time or randomly throughout a day or month.

Physical inventory results have an effect on stock or production.

Inventory and Processing

Forecast management profiles document permanent stock levels within a system.

Before conducting physical inventory in ERP, commodities should first be imported to SAP EWM before doing a physical count in ERP. Furthermore, resource papers, packaging units and warehouse bins need to be created within SAP EWM for Physical Inventory to function correctly.

Packing units allow for mixed deliveries that include warehouse bin products as well as product categories.

SAP EWM pdfs and SAP EWM blogs

CloudFoundation is an e-learning Platform offering extensive programs, videos and simulation sessions designed to assist newcomers become productive quickly in EWM basic vs advanced warehouse management Courses.

This Platform is tailored for students, professionals and organizations striving to fulfill their SAP EWM learning goals as it is constantly updated.

SAP EWM blogs provide an ideal means of exploring its capabilities. From basic training, insights and the newest SAP EWM trends as well as solutions such as storage productivity solutions integration data migration or even data migration itself! – these blogs make an excellent educational tool!

CloudFoundation learners have access to SAP EWM pdf documents through CloudFoundation Learning Management system.

Mentors and experienced specialists assist learners in mastering SAP Warehouse Management through this program, customizing solutions specifically to learners’ learning goals while keeping them updated about SAP EWM updates.

Divya

Author