SAP MDG Material Master Online Training

Why SAP MDG Makes Material Master Management So Intuitive?

Now I understand why SAP MDG promotes shifting away from MM01 towards more modern interfaces, such as NWBC and Fiori.

By matching material type with user behaviour, SAP MDG ensures clarity and precision for MRP/accounting views that appear only when necessary, streamlining the user experience.

As I experimented, it quickly became evident that SAP MDG responded to my choices by adapting accordingly. Selecting sales organisations with enhanced data visibility while excluding those that weren’t applicable led to unnecessary views being removed.

These flexible features make SAP MDG an ideal solution for managing complex data flows with minimal confusion.

Every time I created or reviewed materials with SAP MDG, a clear path forward was provided: it validated my entries, presented relevant fields and kept everything organised.

SAP MDG goes beyond simply managing data; instead, it empowers its users to interpret it strategically and manipulate it purposefully.

SAP MDG Functional Aspects

Working on SAP MDG projects has shown me the value in understanding both how to utilise and support its functionality.

When creating new material masters, I ensure that all dependent elements, such as base units of measure and purchasing groups, are set correctly before proceeding with the setup.

For instance, when I don’t see a material group listed, I check its configuration through SPRO or other appropriate tables to ensure users always have all necessary supporting data available when creating master data in SAP MDG.

Remarkably, SAP MDG relies heavily on ECC configuration for workflows and governance functions. Therefore, I never neglect foundational data models and transport requests tied to them if I want SAP MDG to run efficiently and meet compliance requirements.

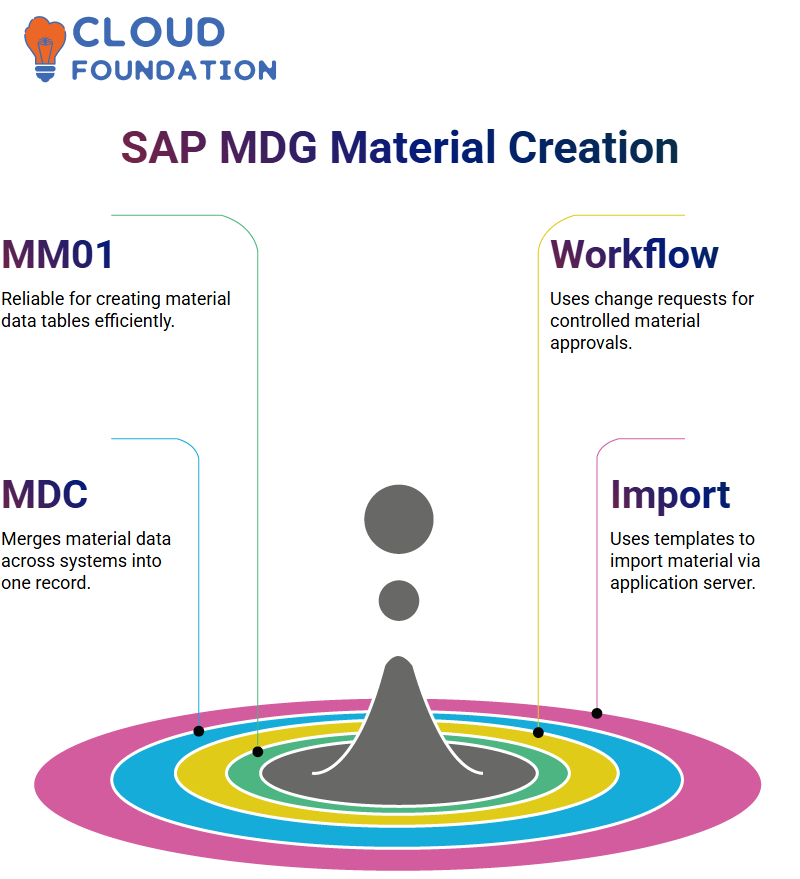

SAP MDG: Material Master Creation Techniques

As part of SAP MDG, one of the key concepts I encountered was material masters. There are various efficient means for creating material masters; I found transaction code MM01 to be the most reliable for making these data tables.

Beyond MM01, I explored material creation through SAP MDG workflow processes.

By initiating change requests within MDG and following its governed workflows for materials production, traceability, and approvals, the creation process can maintain these controls.

SAP MDG’s Master Data Consolidation (MDC) tool is also an indispensable resource, especially when merging or consolidating material data across systems into one single record. Although more advanced, I plan to offer an in-depth session about MDC at a later time.

Custom programs utilising SAP MDG Data Import Framework provide another exciting approach I take in material creation using structured templates – typically Excel or CSV files from local machines or uploaded directly onto an application server.

These four core methods — MM01, workflow, MDC, and Data Import Framework — form the backbone of SAP MDG material creation strategies that I rely on on a regular basis.

SAP MDG Material Creation and UI Behaviour

Created a material in SAP MDG, which gave me insight into its user interface (UI), especially as I entered information such as plant and sales organisation into fields; the system automatically adjusted the view settings.

For example, entering an active plant revealed MRP views and scheduling, while selecting a sales organisation revealed tax-related fields. The responsive nature of SAP MDG is evident in both environments.

Additionally, SAP MDG differentiates between purchasing groups and sales organisations to give a seamless user experience.

While plant and sales organisation data are displayed within the material master, purchasing organisation information is not.

Instead, there’s a separate field called the purchasing group field designed to categorise purchasing responsibilities.

SAP MDG enabled me to easily switch sessions, experiment with configuration options, and witness firsthand how master data adapts over time.

Regardless of whether I used NWBC or SAP Fiori as my interface platform of choice, SAP MDG consistently displayed views dedicated to material types appropriately.

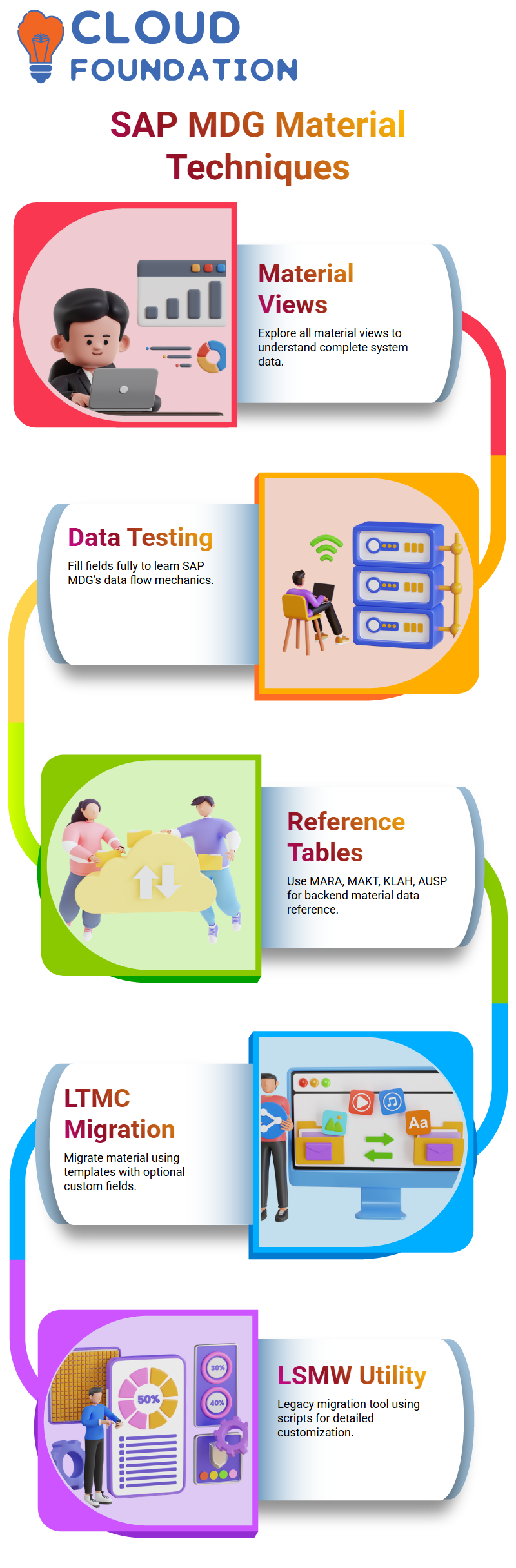

Creating Material in SAP MDG

Creating a material in SAP MDG is more than simply entering basic data; I strongly advocate exploring all views — basic, sales, purchasing, and plant-specific — to gain a thorough understanding of what the system is recording.

Testing SAP MDG requires filling as many fields as possible to understand its data flow between modules, with the MARA and MAKT tables serving as backend sources for basic material information and material descriptions, respectively.

By populating all possible fields during my testing sessions, I learn more about its data handling mechanisms than I would by filling one field at a time in SAP MDG.

As soon as data enters SAP MDG and backend tables such as MAKT, store information about basic materials.

I use tables like KLAH or AUSP to track classification. SAP MDG makes it simple for me to identify where data falls; exploring those structures gives me much-needed confidence boosts.

SAP MDG Material Creation via LTMC and LSMW

Let’s dive a bit deeper into LTMC, SAP’s Legacy Transfer Migration Cockpit. As part of SAP MDG, I often use this tool to load material master data using predefined templates in LTMC.

As soon as I complete filling in all the fields on Excel, I upload it directly into SAP’s system. Although LTMC generally complies with SAP’s internal data structures, additional custom fields (11-13) may need to be included when required; I handle this through basic custom coding techniques.

I frequently rely on LSMW (Legacy System Migration Workbench), an older yet still practical data migration utility for project-related migration projects.

With LSMW, I create scripts and customise fields to meet SAP MDG’s specific requirements – this tool has proven itself indispensable when conventional methods fail me.

Field Descriptions in SAP MDG

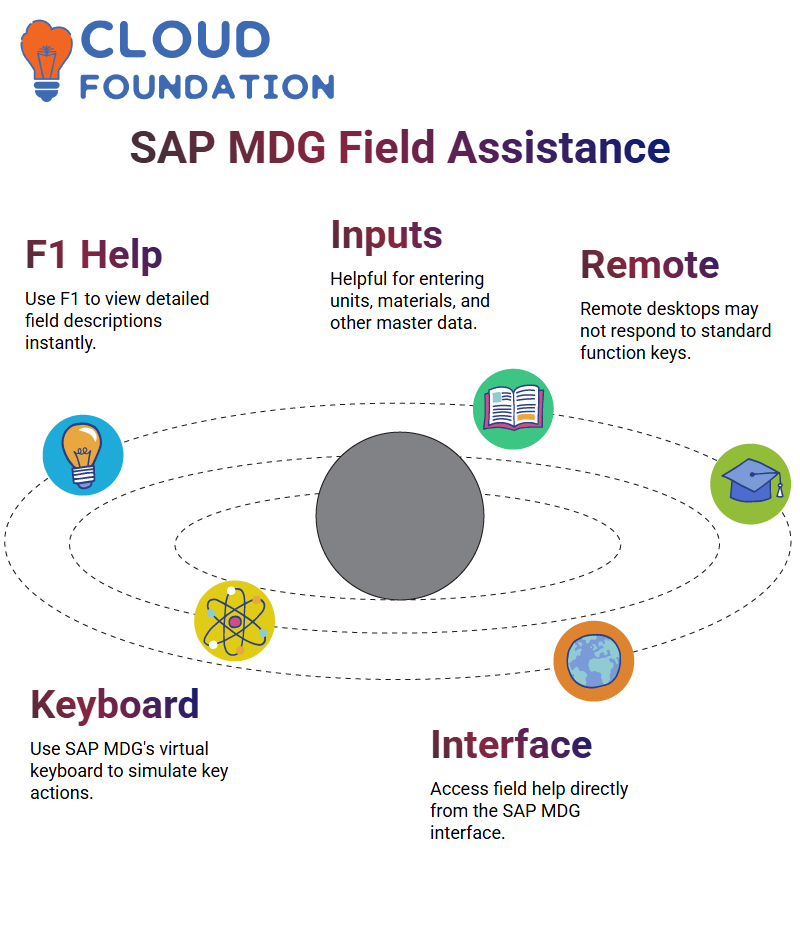

Every field I interact with when working within SAP MDG serves a specific function. To learn what a particular field does, place your cursor over it and press F1.

This provides an in-depth description of each field in SAP MDG, which is particularly useful when creating master data records that require input, such as unit measurements or material descriptions.

Sometimes, remote desktops don’t respond as expected to standard function keys, such as F4 and F1.

When this occurs, I use SAP MDG’s virtual keyboard instead; by clicking on-screen buttons, I can simulate F1 to access assistance directly within the SAP MDG environment.

Classification and Characteristics in SAP MDG

Classification in SAP MDG has long fascinated me. While not mandatory for every material, classification and characteristics play a crucial role for industries with technical specifications, such as aerospace or chemical.

I can provide information regarding colour, tolerance, operating temperature or any physical properties essential to understanding what makes up my material of interest.

SAP MDG enables me to link specifications through classes and characteristics stored in structured tables.

However, not every material requires this level of detail; service materials typically don’t necessitate such extensive classification processes.

However, finished products typically require this metadata to ensure accuracy and compliance with regulations.

Plant, Storage, and Accounting Data in SAP MDG

Once I have passed the basic and classification views, I move into plant data storage, where MARC handles general plant data, while MARD stores plant storage information.

With SAP MDG, I can define where materials are stored at each location, down to the storage bin level if required.

Sales views direct me towards MVKE and MLGT for tasks related to tax classifications and warehouse data, particularly MLGT, which tracks warehouse type settings.

I also enter accounting data into SAP MDG via MBEW, which contains price control, valuation and costing information.

Each view links back to a material number, providing a complete lifecycle view for any product in a single record.

Sales and Tax Configuration in SAP MDG

Configuring sales data in SAP MDG is a crucial aspect of its operation. I use MVKE for sales organisation details and check tax classifications with MLAND to inform the system which tax classification applies based on material type and country.

Ensuring that my tax data is accurately filled into SAP MDG helps prevent errors during invoice processing later on.

I know a single tax class missing can delay entire workflows, so I make it my business to check these values to ensure their accuracy.

Configuration Dependencies in SAP MDG

While configuring material masters within SAP MDG, I have come to appreciate its out-of-the-box configurations as being essential in successfully configuring material masters.

Suppose you need to create a new material group. In that case, Transaction SPRO offers easy navigation of its relevant settings – I often locate my target material group quickly by searching in IMG for “Material Group.”

Material group configurations reside in table T023. I utilise SM30 to view or add entries; recently, I said one directly through this interface labelled ’03 – Test Material Group’.

Note that any modification to material groups creates either customisation or workbench transport requests, depending on its nature.

V_T023 has become my go-to view for inspecting material group values within SAP MDG, providing users with access to viewing appropriate values when creating materials in MDG and supporting an effortless MDG experience. These fundamental configurations help ensure its smooth running.

Navya Chandrika

Author